| Availability: | |

|---|---|

| Quantity: | |

ZM-SSSF

ZEEMO

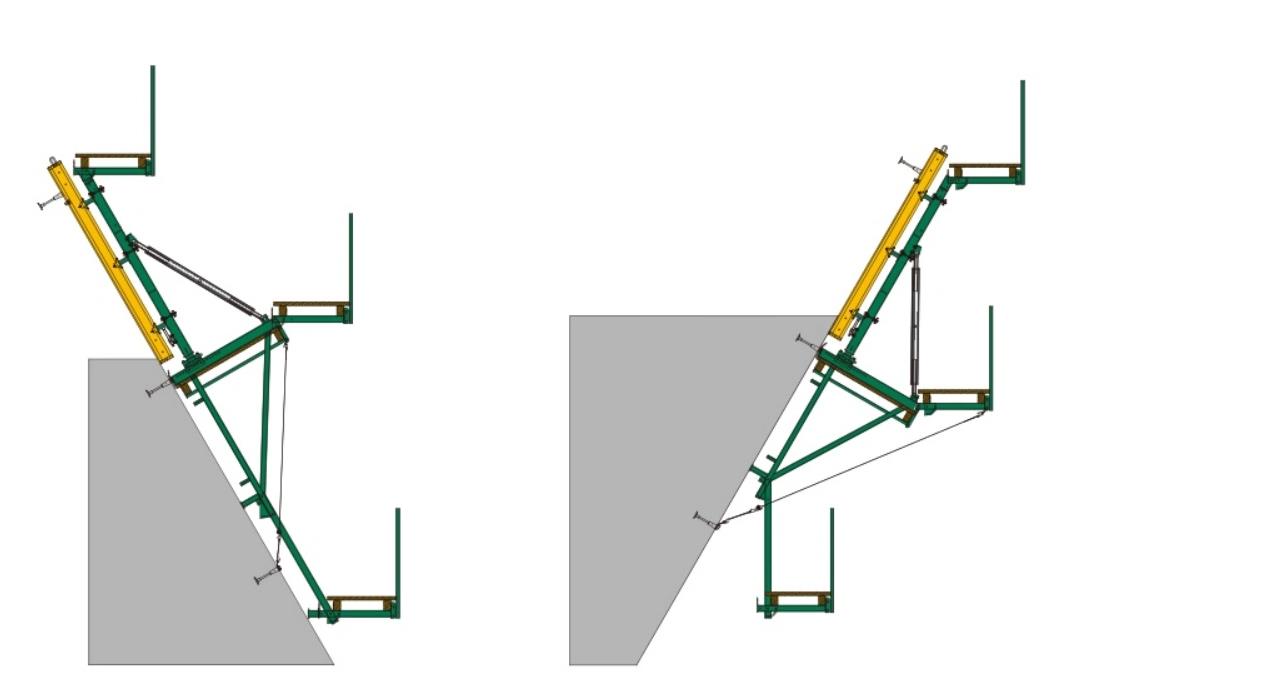

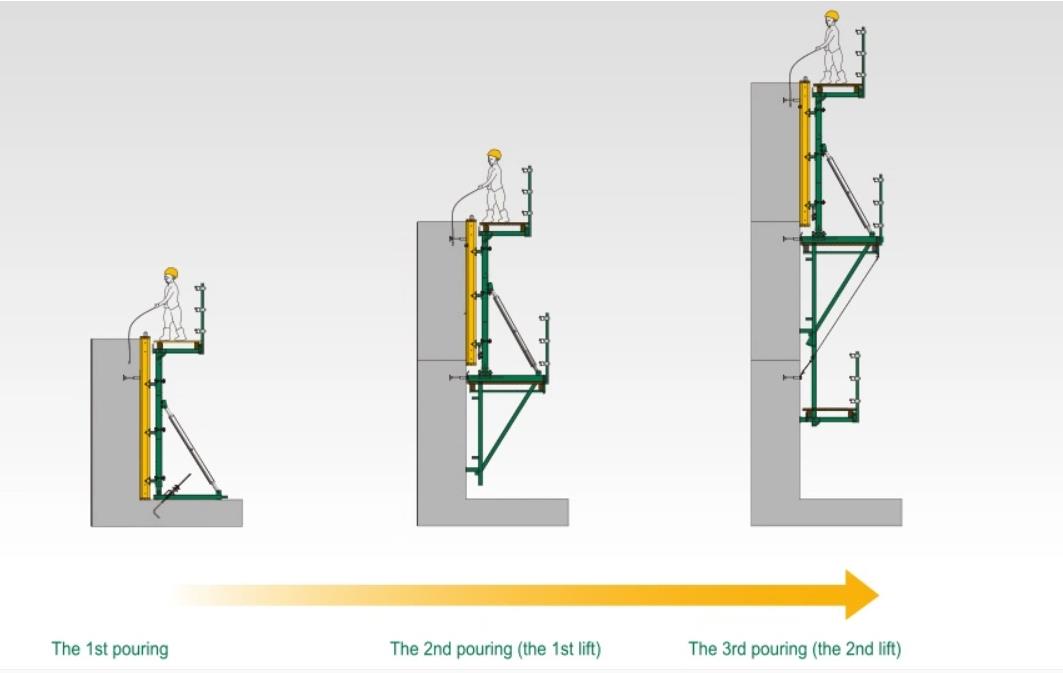

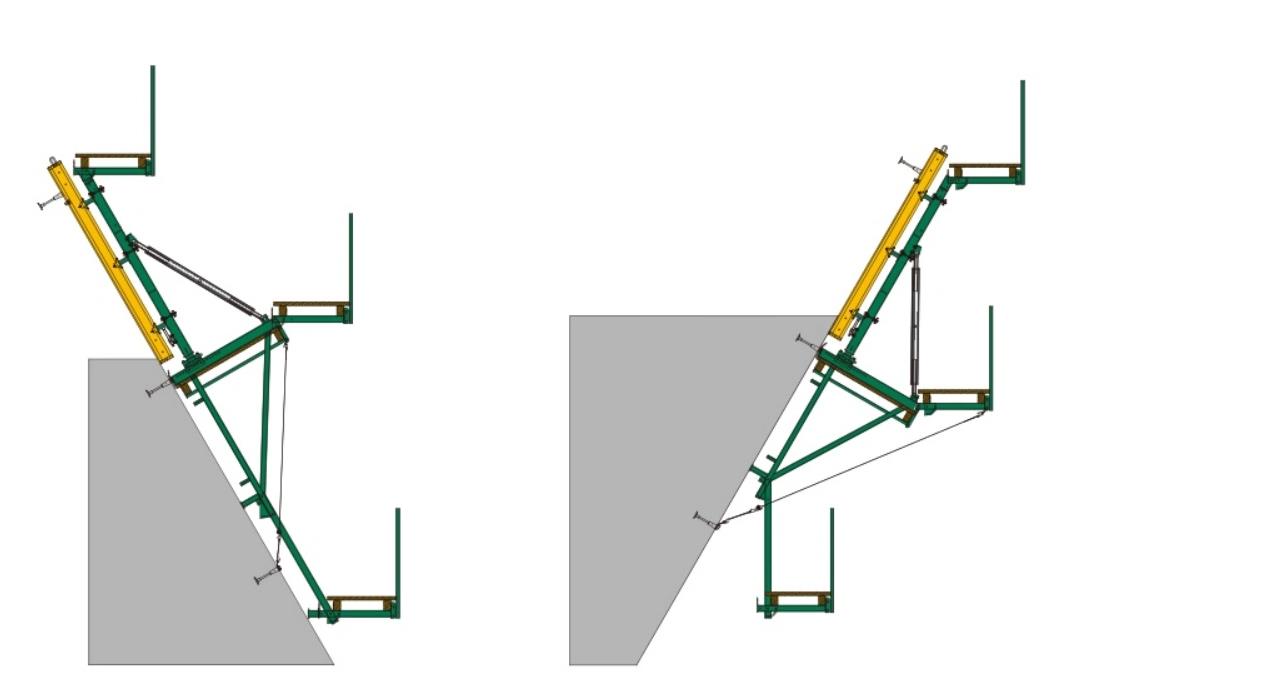

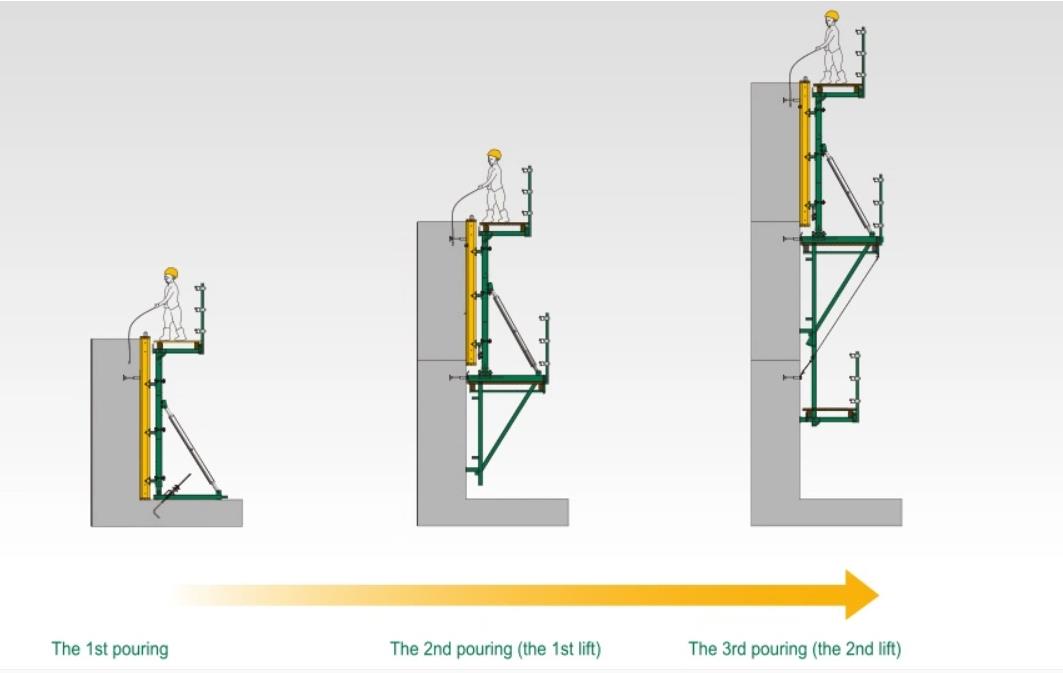

SS-186 system can be adjusted forward and backward. The Max. angle is 30°.

Products Display:

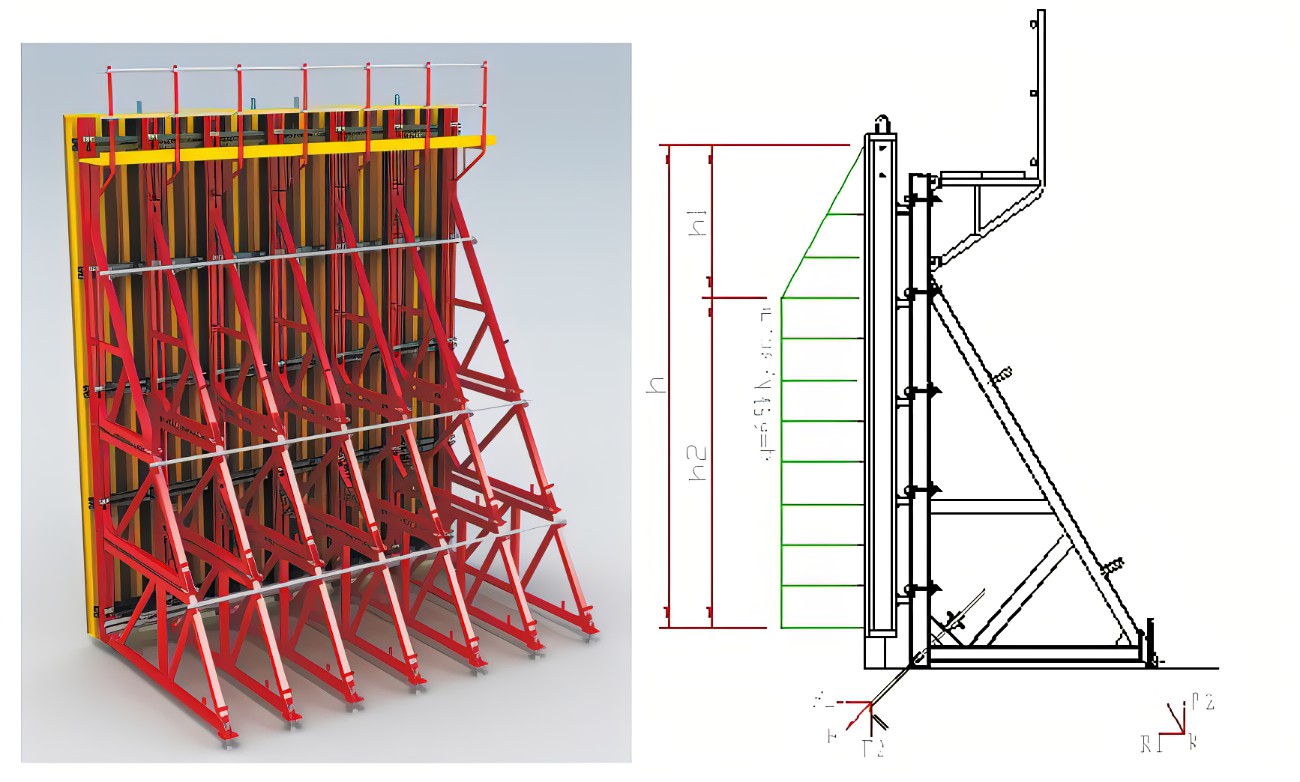

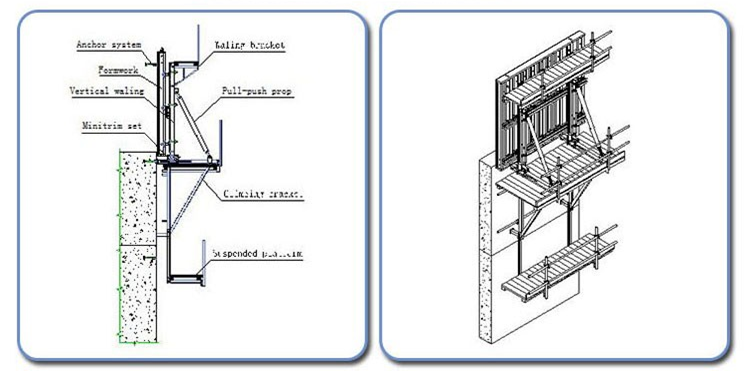

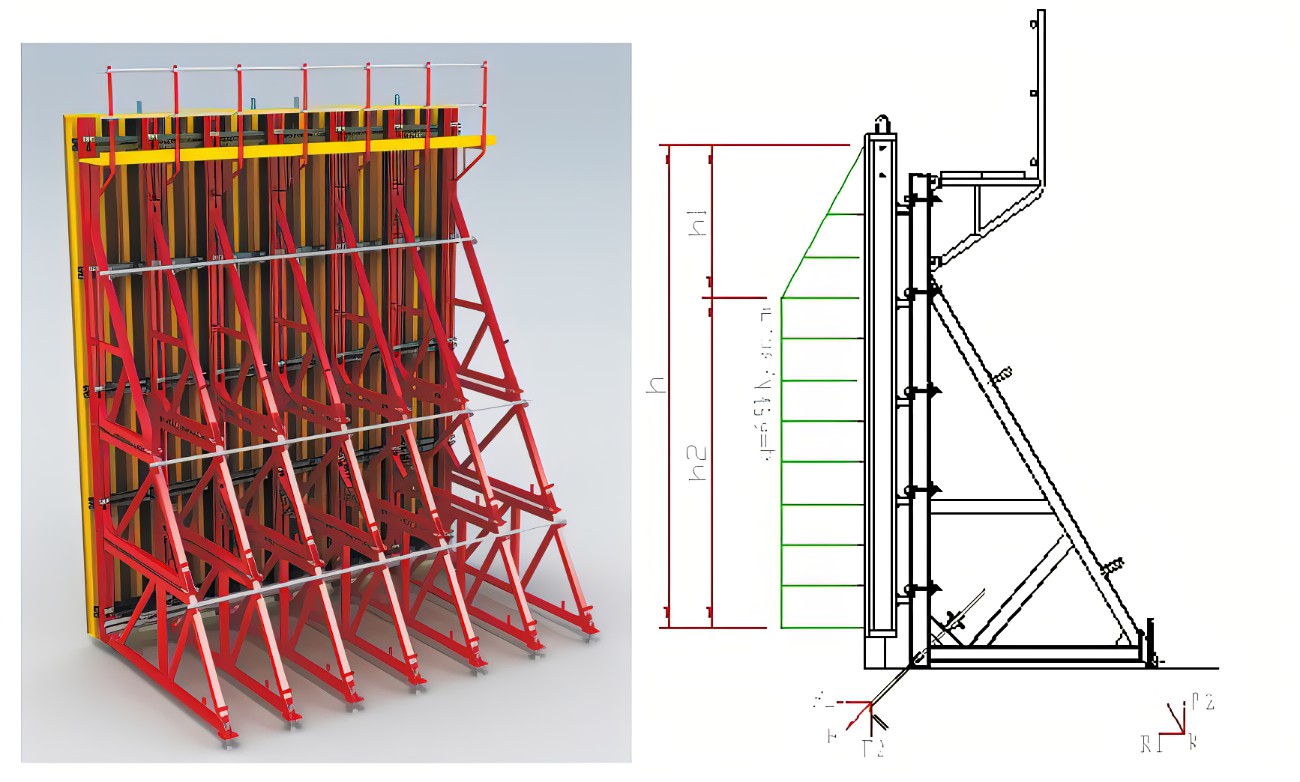

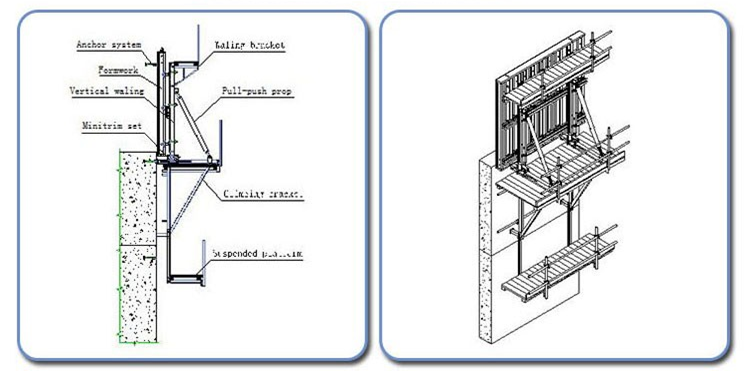

| 1 | WALING/WALER | 2*[12] Q235 |

| 2 | BEAM | H20 BEAM |

| 3 | PLYWOOD | 18MM FILM FACED PLYWOOD |

| 4 | ANCHOR SYSTEM | Tie rod, big plate nut, anchor waling, gasket, connection nut, angle anchor rod |

| 5 | ACCESSORIES | scaffolding bracket, waling bracket holder, adjustment jack |

SS-186 system can be adjusted forward and backward. The Max. angle is 30°.

Products Display:

| 1 | WALING/WALER | 2*[12] Q235 |

| 2 | BEAM | H20 BEAM |

| 3 | PLYWOOD | 18MM FILM FACED PLYWOOD |

| 4 | ANCHOR SYSTEM | Tie rod, big plate nut, anchor waling, gasket, connection nut, angle anchor rod |

| 5 | ACCESSORIES | scaffolding bracket, waling bracket holder, adjustment jack |

Intimate service will cover the whole process.Please rest assured to cooperate with us!

CULTURE:We are one family, members care each other, cooperate intimately, we sharingdream, idea and love in family. We holding same duty-- to serve clients.

Intimate service will cover the whole process.Please rest assured to cooperate with us!

CULTURE:We are one family, members care each other, cooperate intimately, we sharingdream, idea and love in family. We holding same duty-- to serve clients.