| Availability: | |

|---|---|

| Quantity: | |

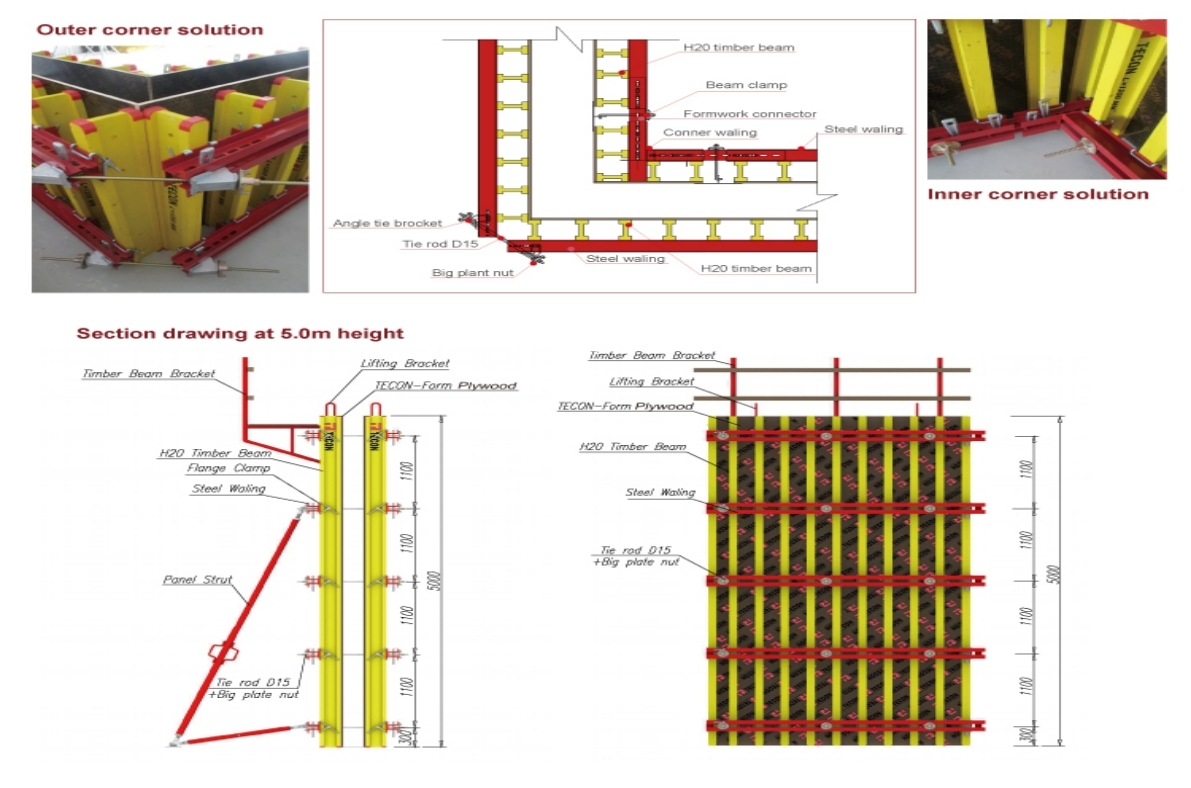

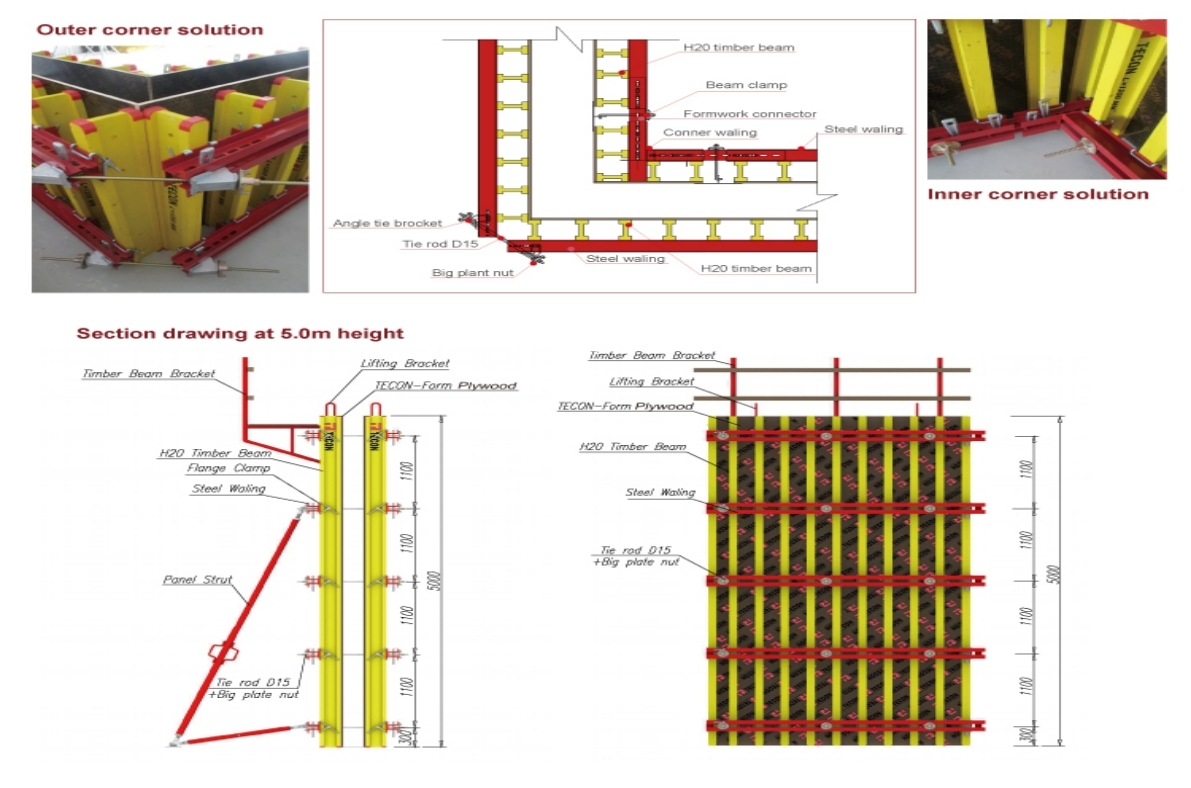

ZM-SWF

ZEEMO

| MAX Pouring Height | Plywood | Weight | Leading Time |

| 9 meters | 18mm hardwood | 65kg/SQM | 35 days |

| MAX Pouring Height | Plywood | Weight | Leading Time |

| 9 meters | 18mm hardwood | 65kg/SQM | 35 days |