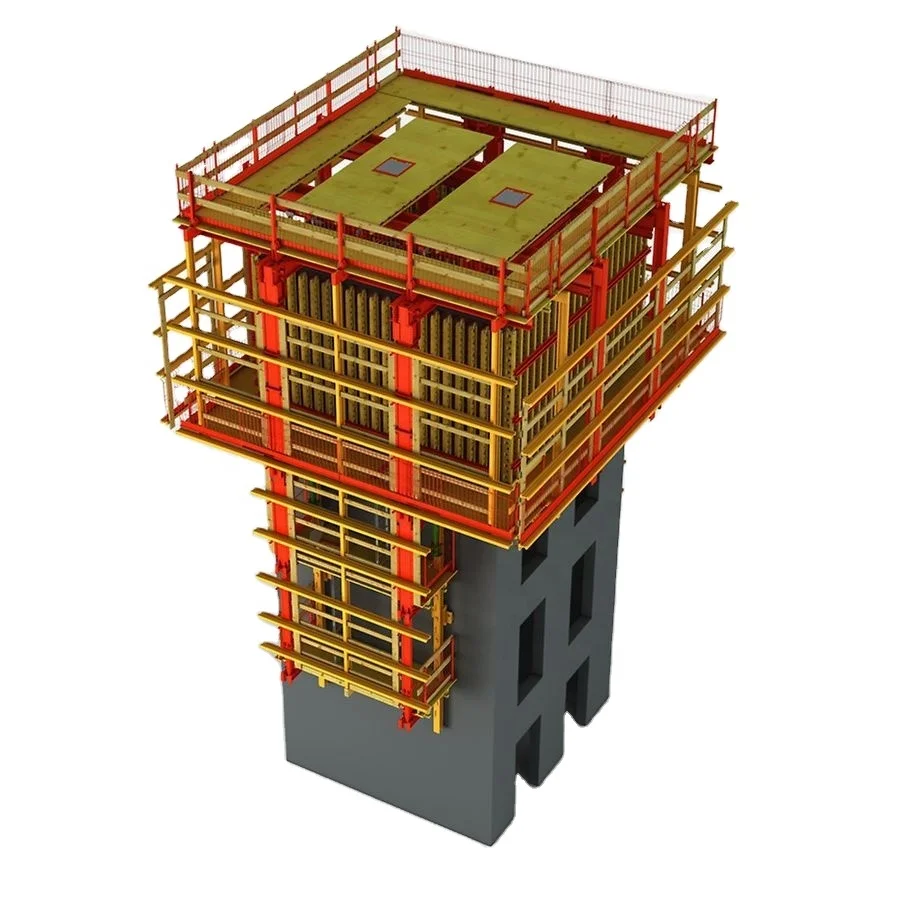

INSTALLATION INSTRUCTIONS

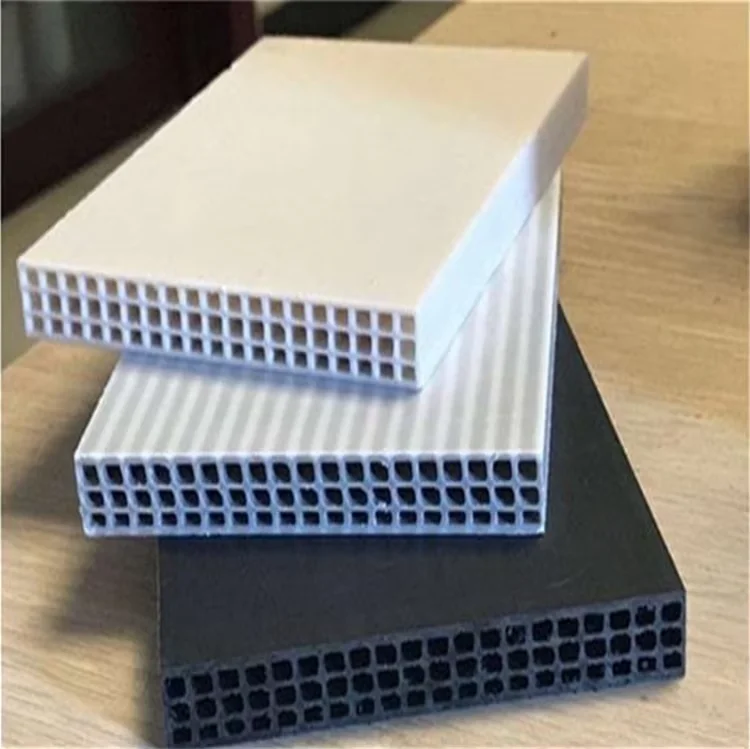

1. Use the hollow building formwork intersecting surface laid with 15mm thick.

2. Wood square of the distance: (1) on the surface of the intersection (spacing: wood square distance according to the thickness

of the slab concrete, in general, the thickness of less than 0.15 m floor (spacing is 200 ~ 250 mm.(2) the shear wall (spacing

according to adjust the spacing, height and thickness of the wall to wall height of 2800 mm, 300 mm thick wall, for example, using

the formwork (15 mm thickness spacing is 100 ~ 150 mm, if the shear wall, pillar width more than 1 meter, must add the fixed

frame.

3. Die shear wall and column puzzle when leaving no gaps, internal Angle (the bottom of the wall) parts must have wood square,

beam, wall, formwork connection.Shear wall made 4 after the mold must be assembled into the whole hoisting, then lay flat, reduce

labor intensity, forming effect is good.

4. When the nail to the formwork from the formwork edge distance 15 ~ 30 mm, strength wants moderate, nail nails is 40 ~ 50 mm in

length, shoulds not be too long or too short.

5.Beam bottom of a piece of wood square must set aside 15 mm seam allowance, wallboard made on wood square seam allowance, it does

not leak slurry and wallboard material saving.

Industry Market Analysis

Plastic and steel, wood and cement are collectively called the four building materials. Building formwork market demand is

increasing year by year, every year nearly 220 million square meters of bamboo/wood are used to produce template.

The shortage of wood source lead to import timber price rising. Besides, the wooden formwork is not recycled which causes a large

waste and operating cost of construction.Plastic template is a kind of energy-saving and green environmental protection products.

Replace of traditional steel template and pine wood template, the amortization cost is low.

Building templates-plastic instead of wood

In recent years, plastic building formwork have had a fast development in industrial developed countries, and more and more

different standards and kinds are produced, which are widely used in construction project and bridge project, has obtained the

good effect;

plastic template is a renewable green environmental protection energy-saving products, both satisfy the requirement of the

construction technology, improve reuse times, save the wood source and reduce the cost of companies.

Advantages of plastic formwork

1.reuse more than 60 times, long service life.

2.high hardness, good tenacity,no expansion,no shrinkage.

3.Light weight, complete specification, easy to remove, construction operation and transportation safety.

4.waterproof, non-hygroscopic,not layered, not swelling, size stable under the water.

5.The surface is smooth and clean, and the concrete stripping is good, easy to release the mold.

6.bearable temperature:-10-70℃,not deformed (within 1-2 mm) in high temperature.

7.It is easy to clean and maintain, so it reduces the cleaning and maintenance cost of the template.

8.Can be used with wood (bamboo) plywood and other materials.

9.no need oil,easily install and remove, only tapping formwork can be falled off, with out release agent.