| Availability: | |

|---|---|

| Quantity: | |

ZM-PPFFP

ZEEMO

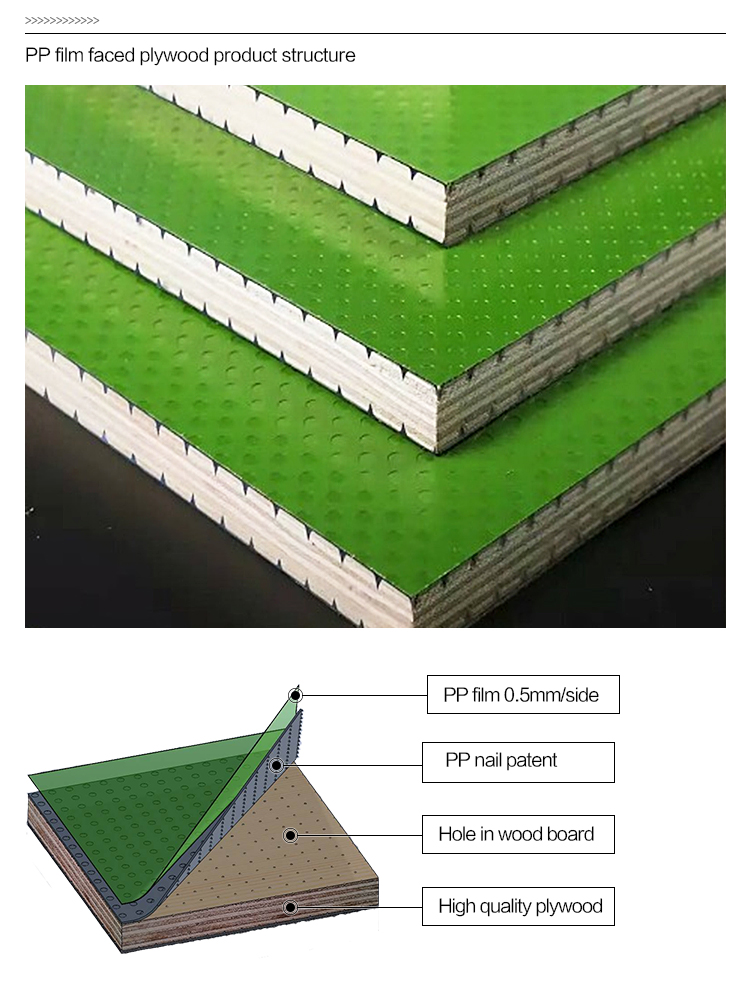

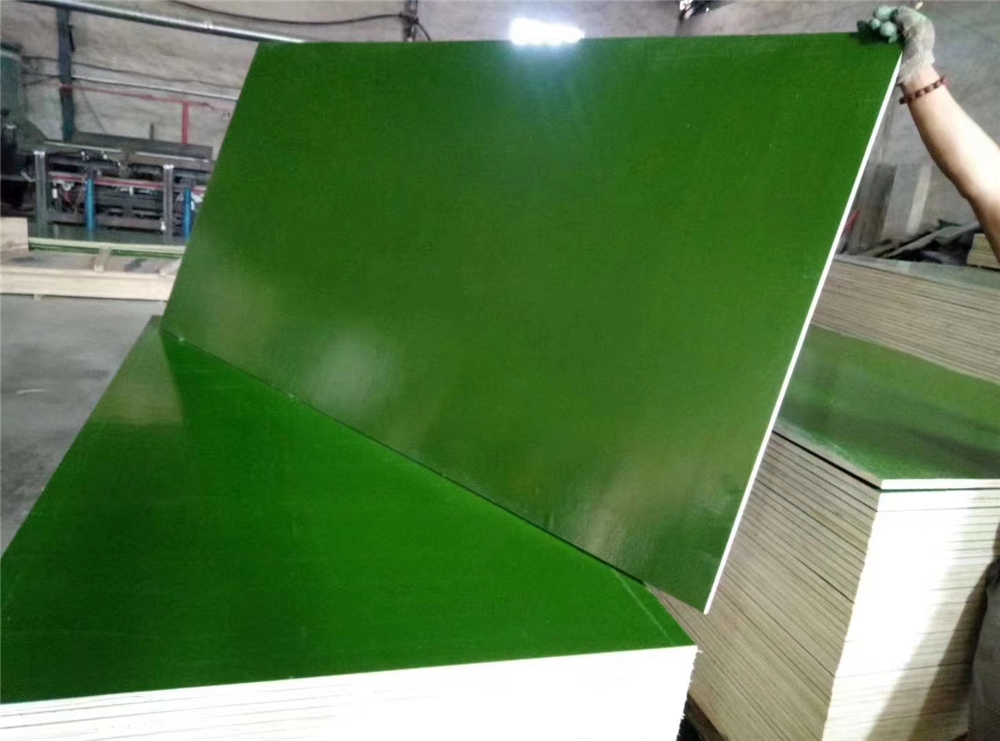

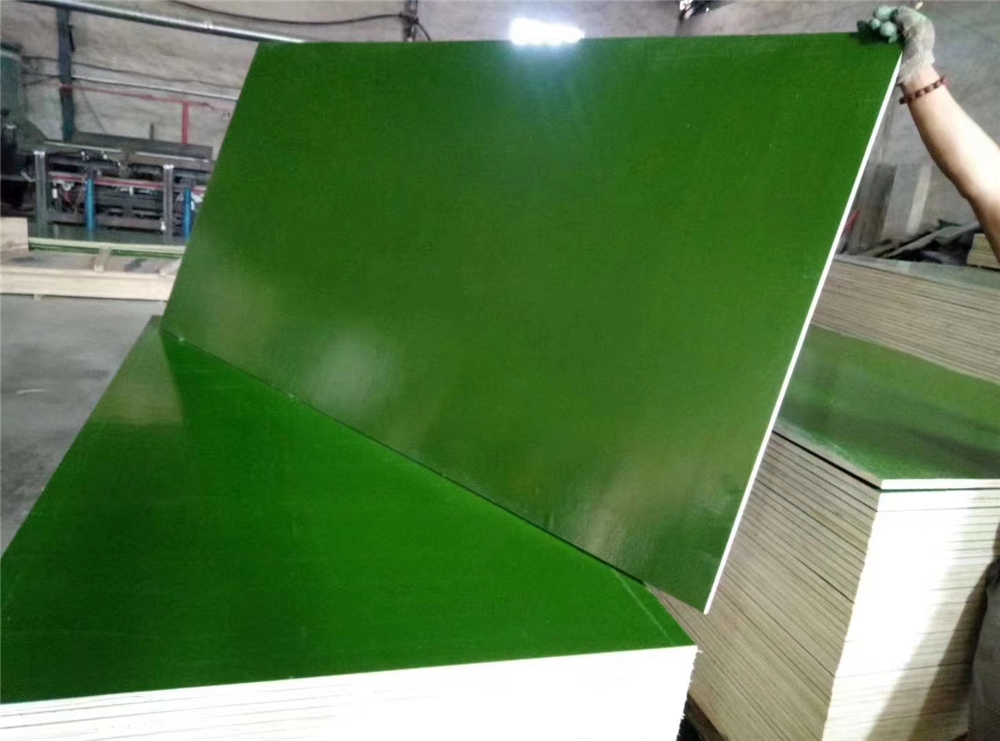

| Name | Plastic Film Faced Plywood | |

| Brand Name | ZEEMO | |

| Size | 1220*2440,1250*2500mm or upon request | |

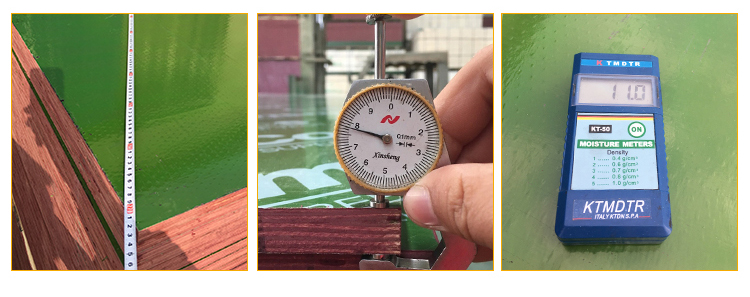

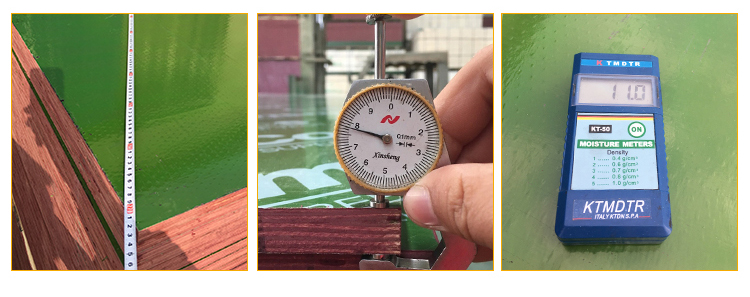

| Thickness Tolerance | 4-25mm or upon request | ±0.5mm |

| Core | 100 %poplar, 100% eucalyptus, birch, pine, or other hardwood or combi | |

| Edge | Sealed with water proof paint, colour can be upon request | |

| Film options: | Domestic Black or Brown film or Dynea film | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Formaldehyde Emission Standards | Carb,E0,E1,E2 | |

| Moisture | 8%-12% at the time of shipment | |

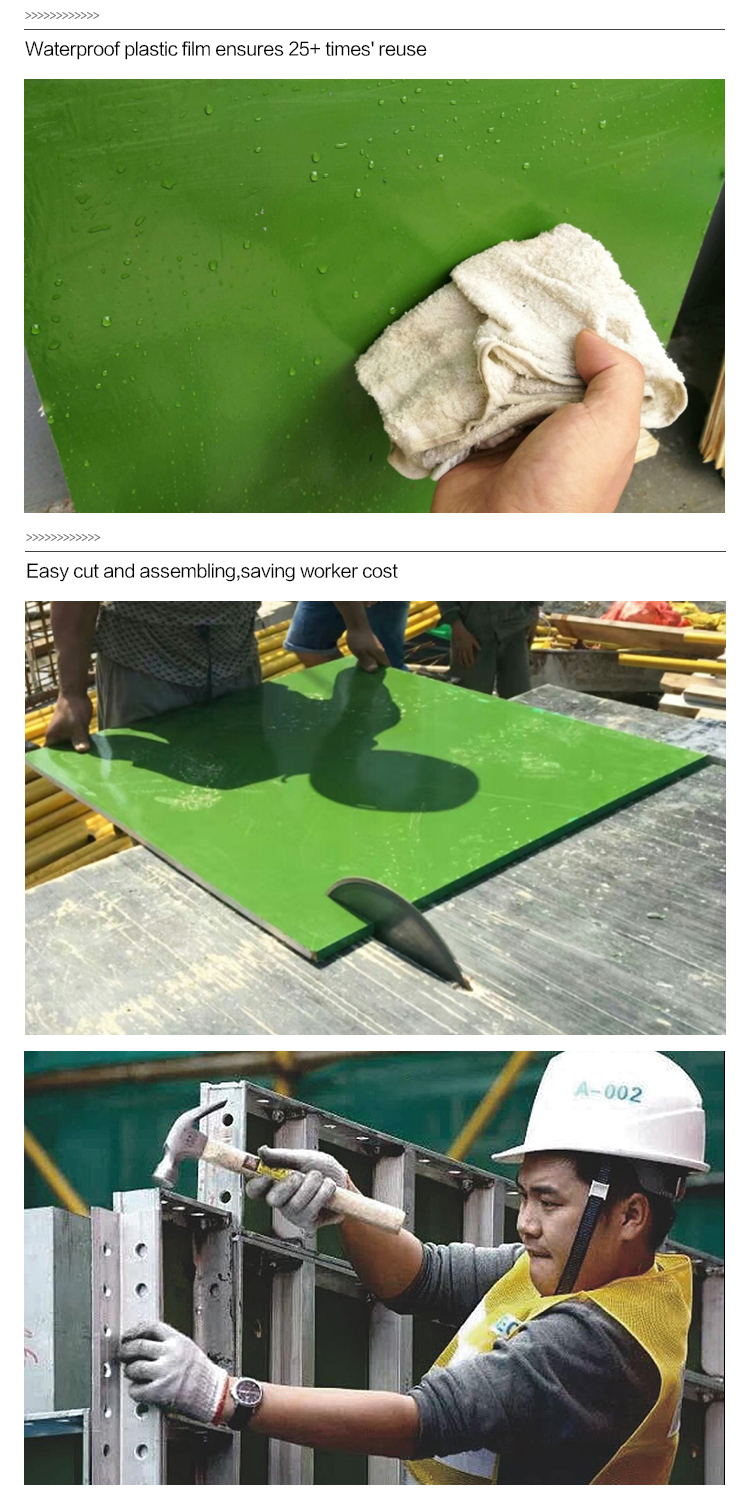

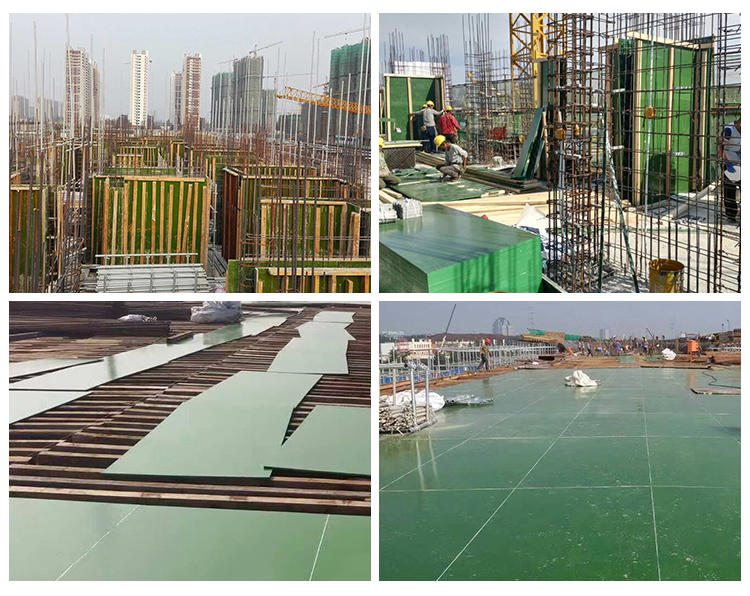

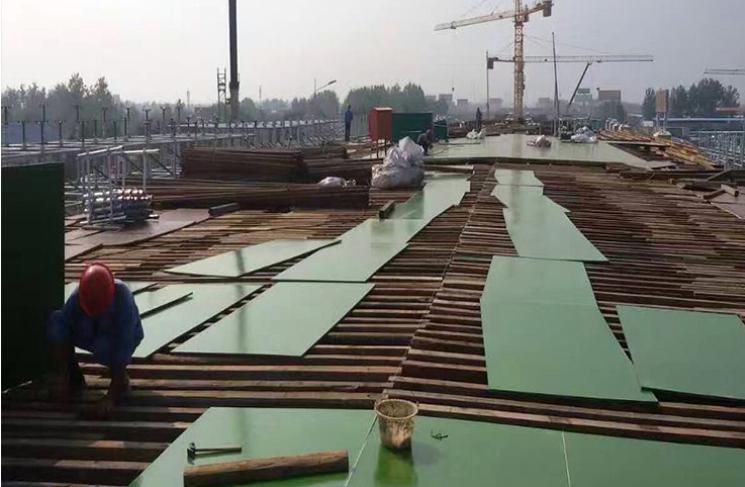

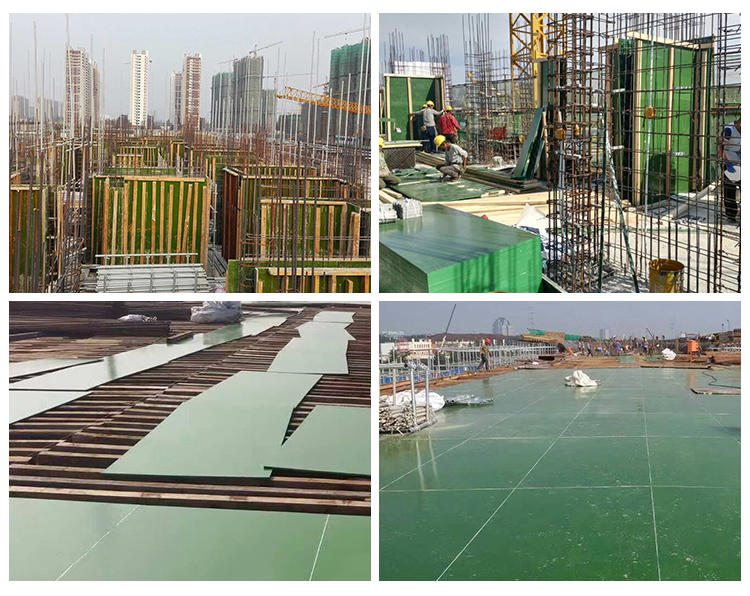

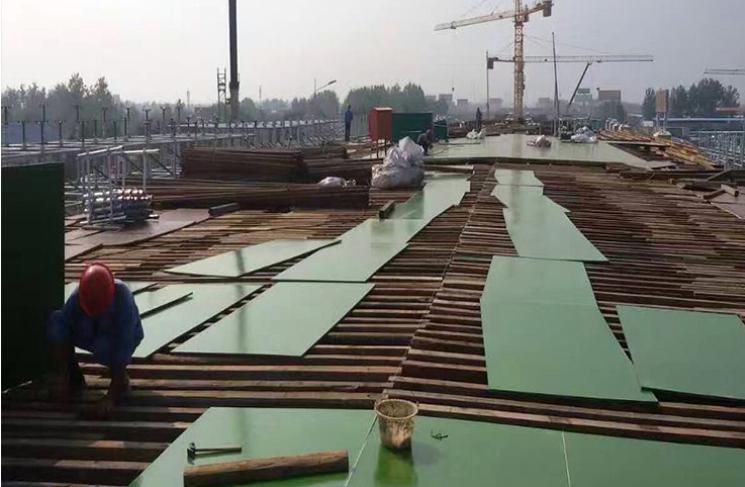

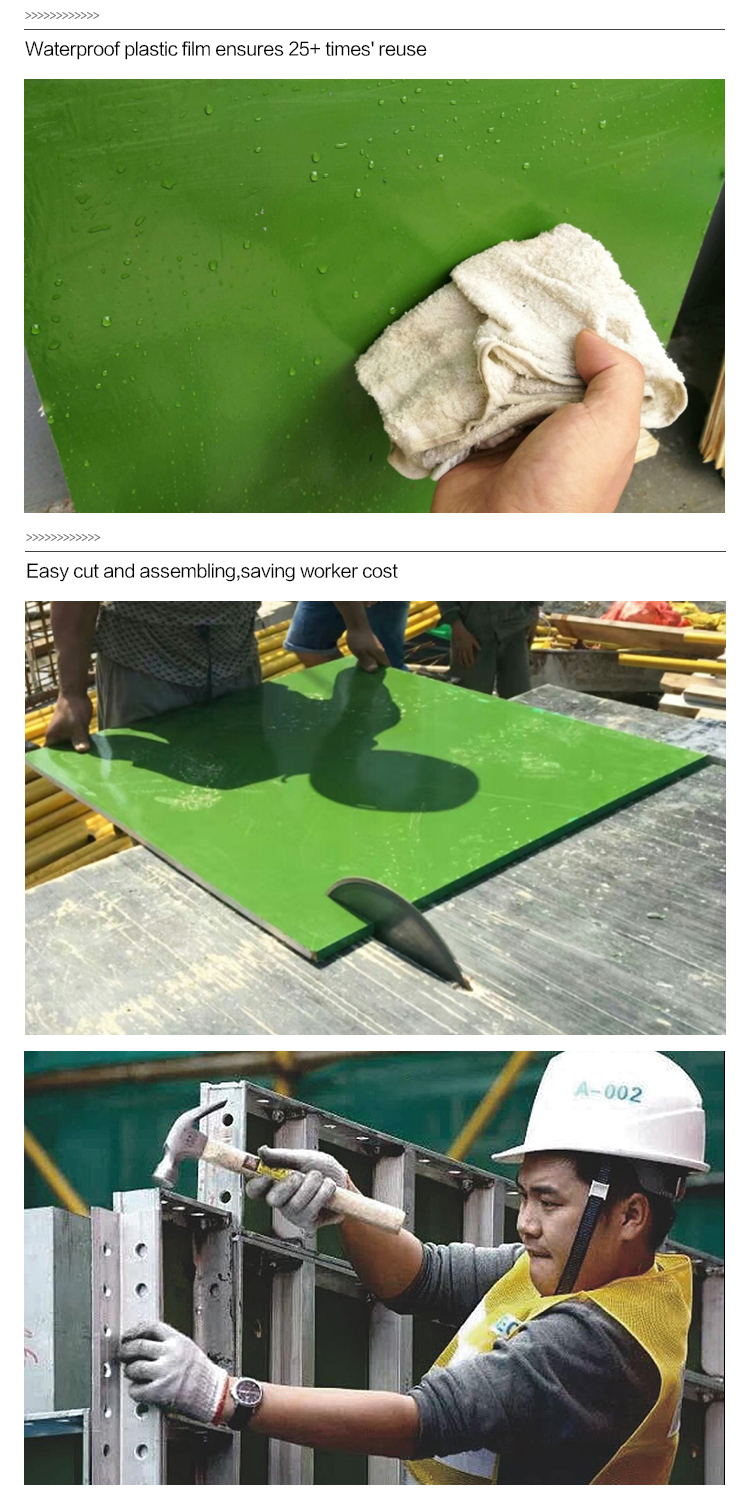

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: Pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO,FSC,CARB | |

| Delivery time | Within 2-3 weeks on the down payment or L/C | |

| Min Order | 1*20'ft | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

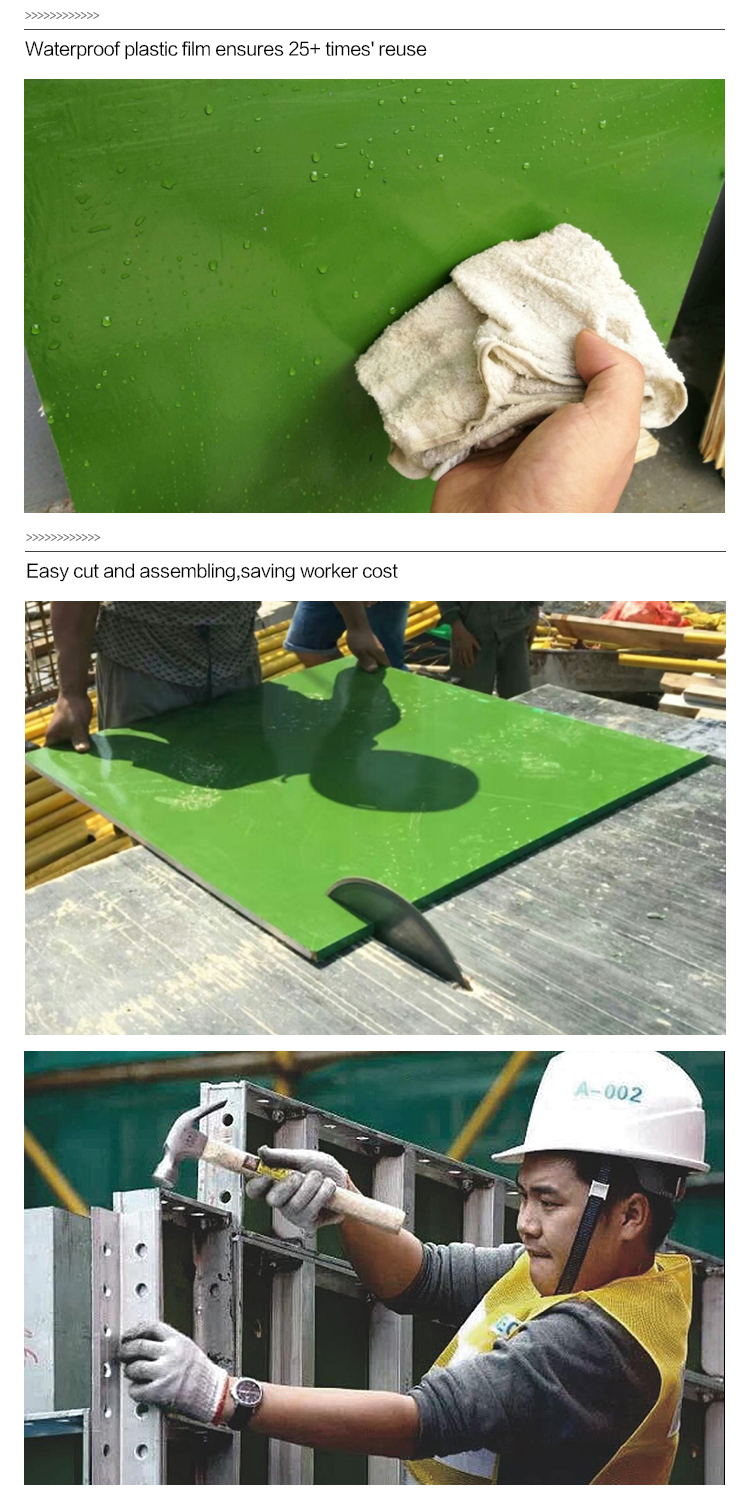

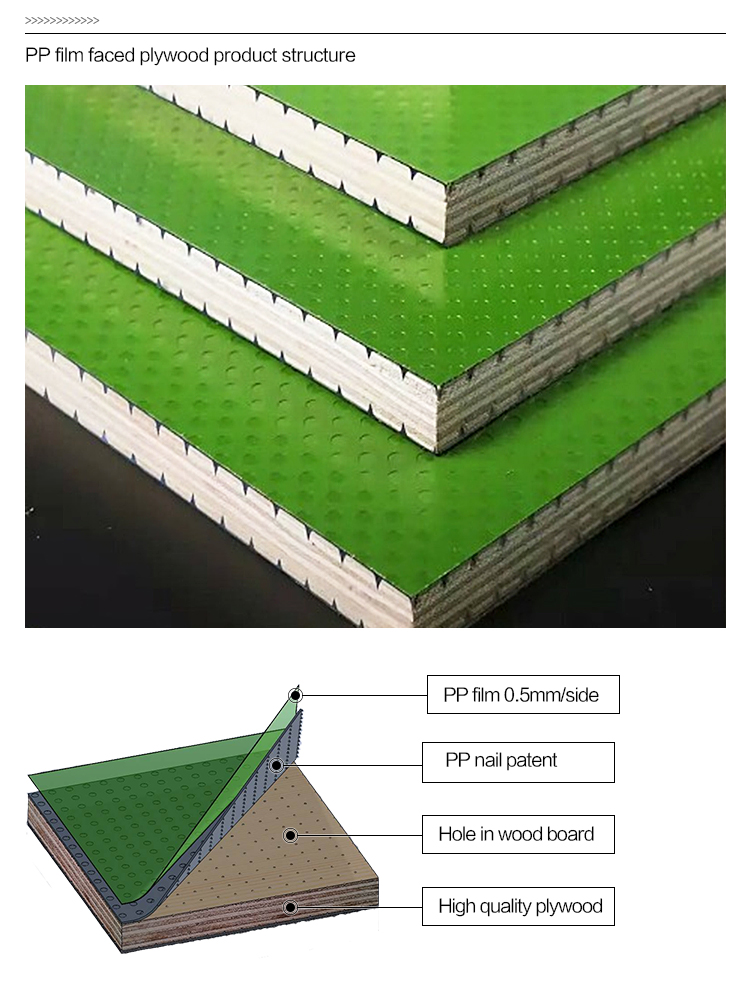

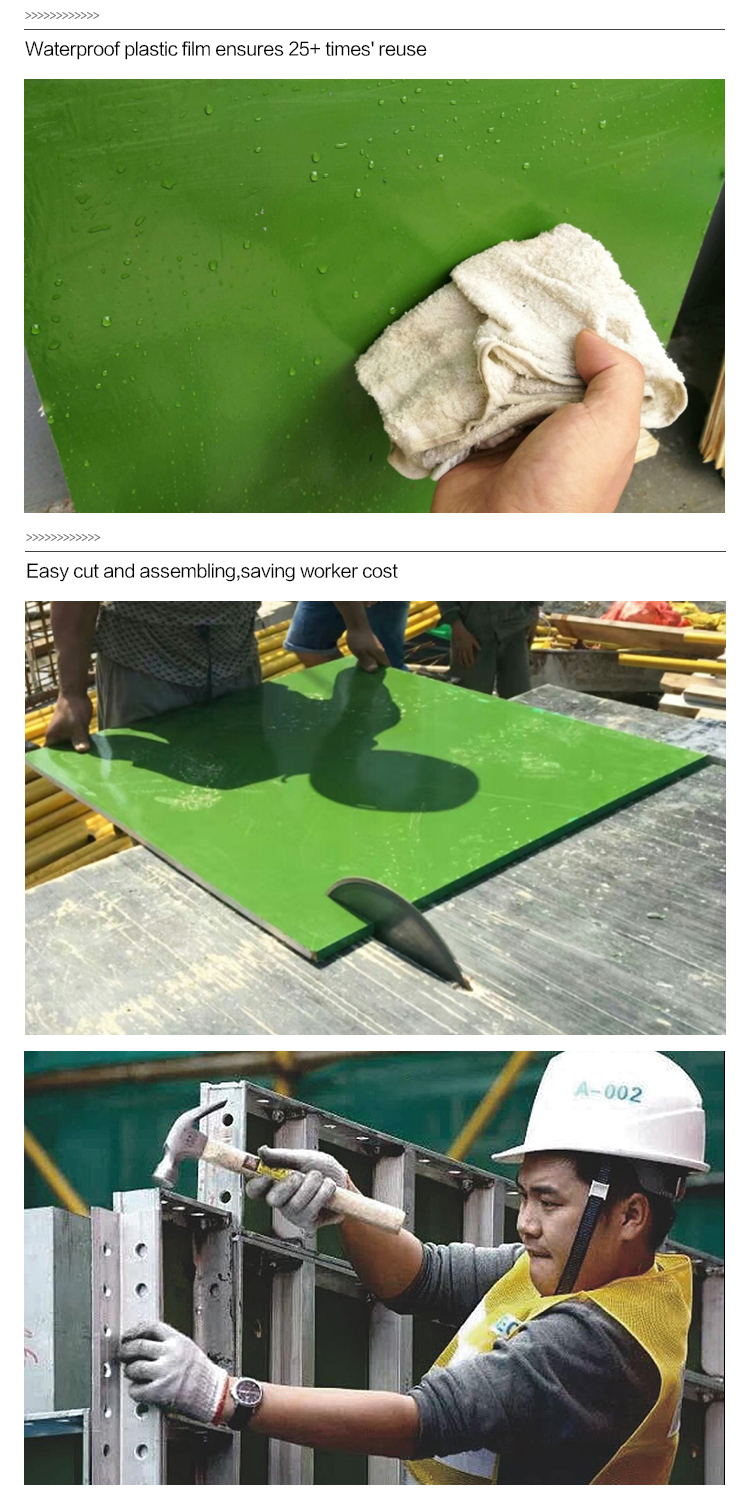

| MARK: | ZEEMO plastic film faced plywood series is our new technical product construction sheet, ZEEMO is using pp plastic anti-wearing film on the high-quality veneer. Both with phenolic WBP glue makes it stronger and increase reused time to 20-30 times. If you are focus on high quality and reused times, ZEEMO is your best choose. | |

| Name | Plastic Film Faced Plywood | |

| Brand Name | ZEEMO | |

| Size | 1220*2440,1250*2500mm or upon request | |

| Thickness Tolerance | 4-25mm or upon request | ±0.5mm |

| Core | 100 %poplar, 100% eucalyptus, birch, pine, or other hardwood or combi | |

| Edge | Sealed with water proof paint, colour can be upon request | |

| Film options: | Domestic Black or Brown film or Dynea film | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Formaldehyde Emission Standards | Carb,E0,E1,E2 | |

| Moisture | 8%-12% at the time of shipment | |

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: Pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO,FSC,CARB | |

| Delivery time | Within 2-3 weeks on the down payment or L/C | |

| Min Order | 1*20'ft | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

| MARK: | ZEEMO plastic film faced plywood series is our new technical product construction sheet, ZEEMO is using pp plastic anti-wearing film on the high-quality veneer. Both with phenolic WBP glue makes it stronger and increase reused time to 20-30 times. If you are focus on high quality and reused times, ZEEMO is your best choose. | |