| Availability: | |

|---|---|

| Quantity: | |

ZM-FFP1

ZEEMO

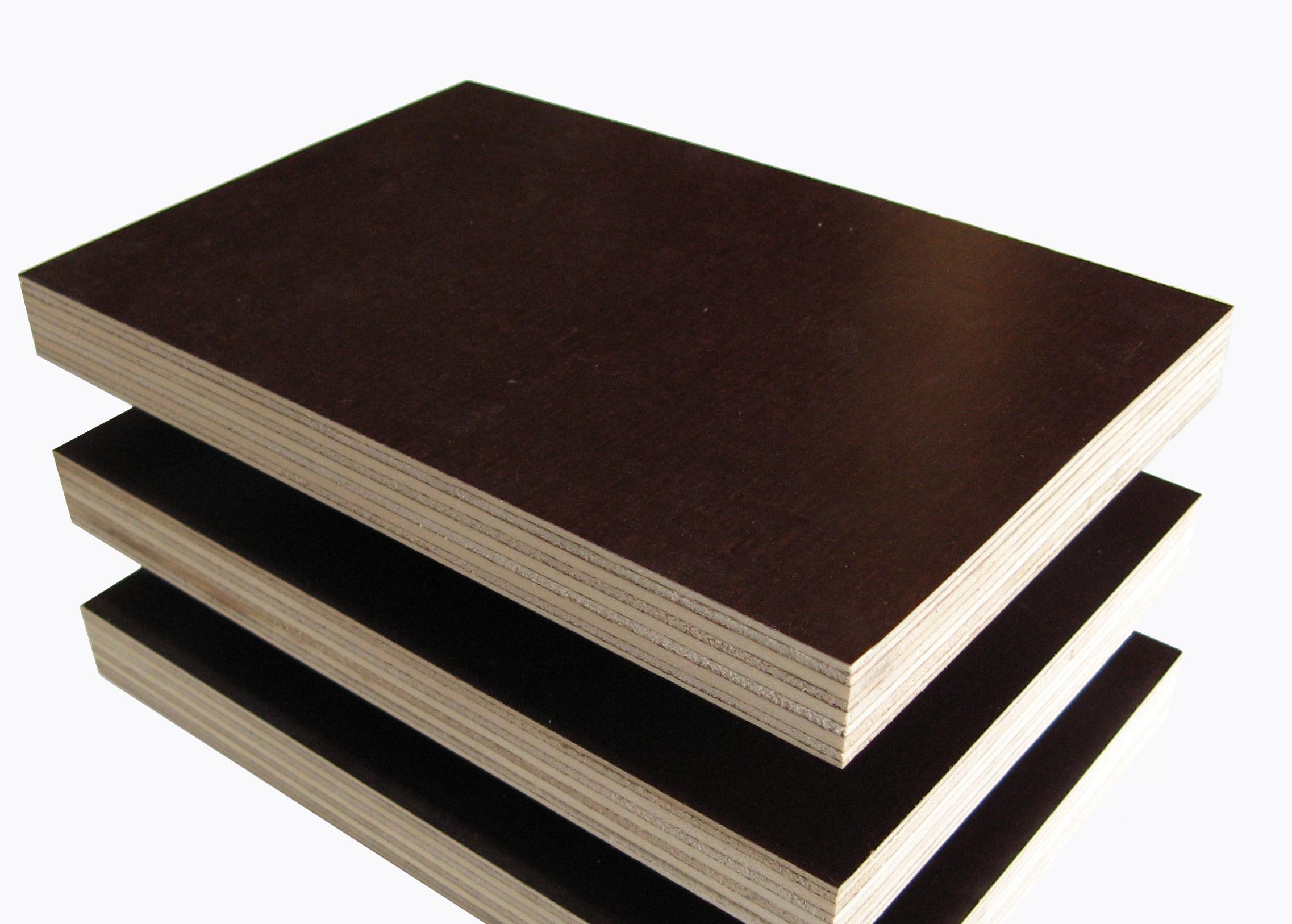

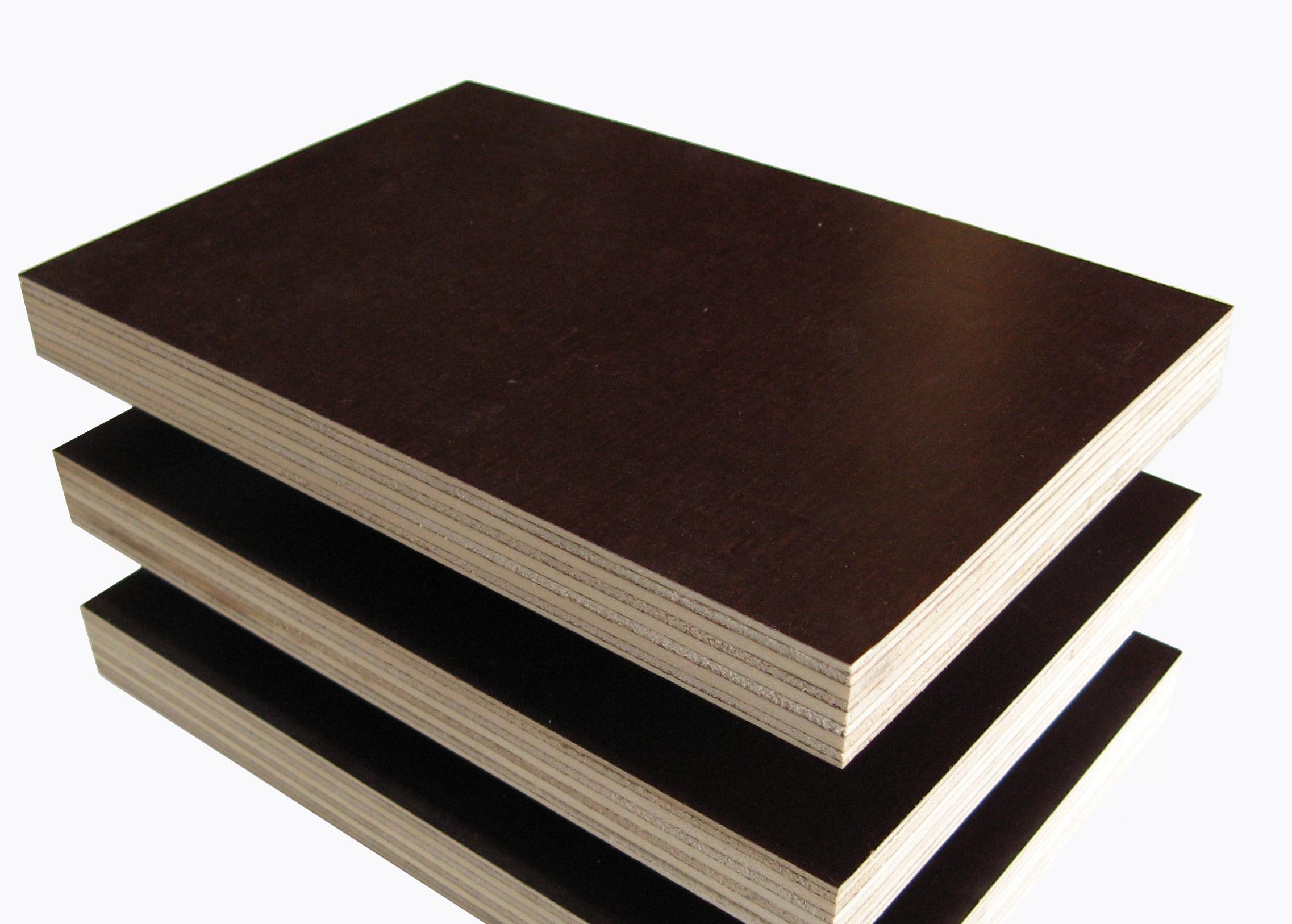

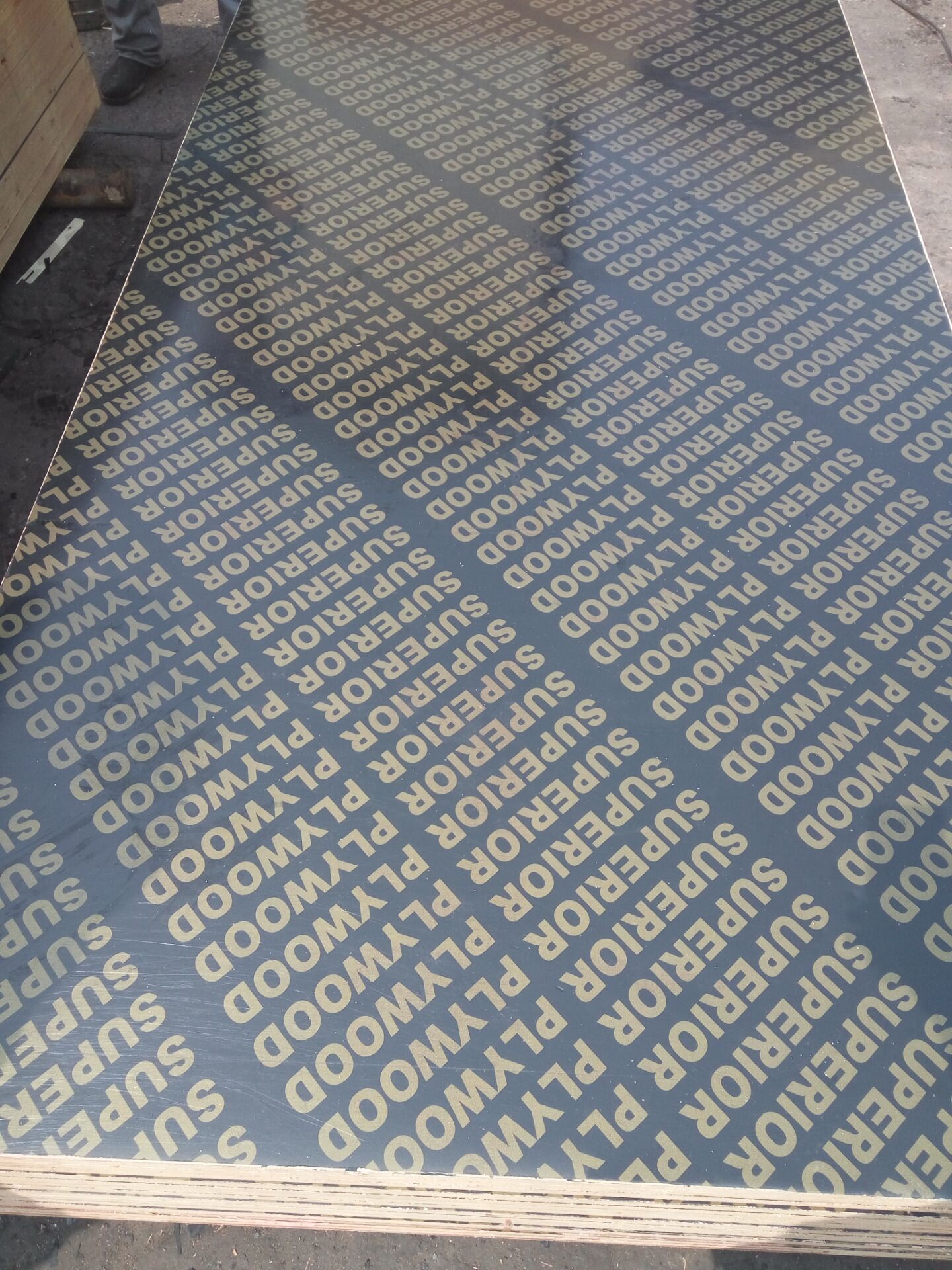

| Name | One Time Hot Press Finger Joint Brown Film Faced Plywood | |

| Brand Name | ZEEMO | |

| Size | 915*1830 mm,1220*2440 mm,1250*2500 mm or upon request | |

| Thickness Tolerance | 9-25mm or upon request | ±0.5mm |

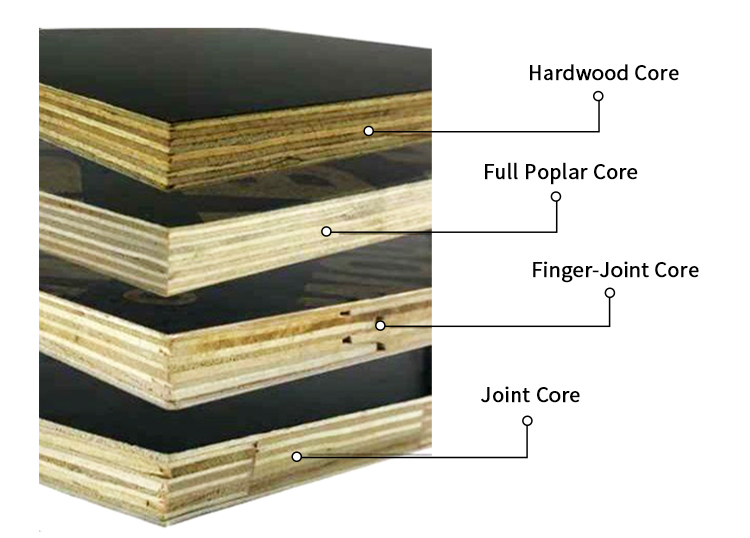

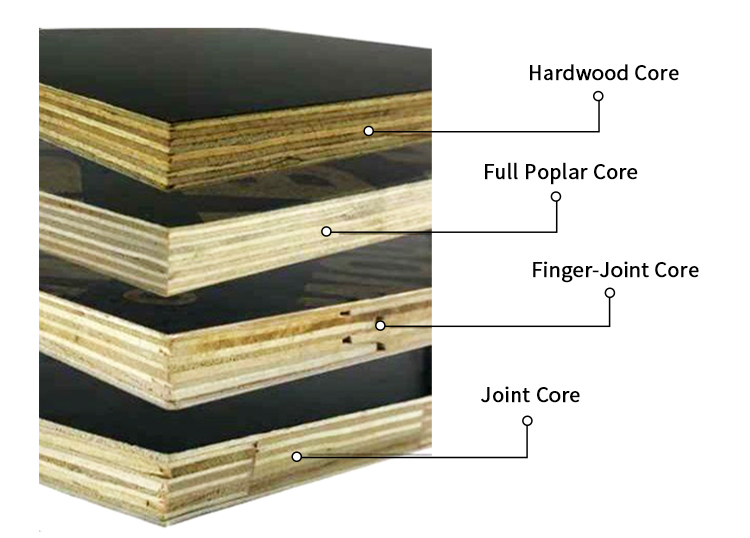

| Core | 100 %poplar, 100% eucalyptus, birch, pine, or other hardwood or combi | |

| Edge | Sealed with water proof paint, colour can be upon request | |

| Film options: | Domestic Black or Brown film or Dynea film | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Formaldehyde Emission Standards | Carb,E0,E1,E2 | |

| Moisture | 12% at the time of shipment | |

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: Pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO,FSC,CARB | |

| Delivery time | Immediately on the down payment | |

| Min Order | 1 piece | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

| MARK: | ZEEMO film faced plywood series is our new technical product construction sheet, ZEEMO is using anti-wearing film on the high-quality veneer. Both with phenolic WBP glue makes it stronger and increase reused time to 20-30 times. If you are focus on high quality and reused times, ZEEMO is your best choose. | |

| Name | One Time Hot Press Finger Joint Brown Film Faced Plywood | |

| Brand Name | ZEEMO | |

| Size | 915*1830 mm,1220*2440 mm,1250*2500 mm or upon request | |

| Thickness Tolerance | 9-25mm or upon request | ±0.5mm |

| Core | 100 %poplar, 100% eucalyptus, birch, pine, or other hardwood or combi | |

| Edge | Sealed with water proof paint, colour can be upon request | |

| Film options: | Domestic Black or Brown film or Dynea film | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Formaldehyde Emission Standards | Carb,E0,E1,E2 | |

| Moisture | 12% at the time of shipment | |

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: Pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO,FSC,CARB | |

| Delivery time | Immediately on the down payment | |

| Min Order | 1 piece | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

| MARK: | ZEEMO film faced plywood series is our new technical product construction sheet, ZEEMO is using anti-wearing film on the high-quality veneer. Both with phenolic WBP glue makes it stronger and increase reused time to 20-30 times. If you are focus on high quality and reused times, ZEEMO is your best choose. | |

Shandong Zeemo Construction Technology Co.,Ltd is a member of Dongstar Group, a multiple industry group in film faced plywood, construction formwork system, scaffolding&accessories. President Wei is nominated as the president of China Shuttering Board Committee.

Our Service

1. Consultancy

Shop drawing, assembly drawing, and even send our supervisor to your site for training and supervision.

FAQ

1. Why Choose Us?

We are a more than 10 years professional manufacturer in formwork with high quality and competitive price.

2. What's your formwork guarantee?

Shandong Zeemo Construction Technology Co.,Ltd is a member of Dongstar Group, a multiple industry group in film faced plywood, construction formwork system, scaffolding&accessories. President Wei is nominated as the president of China Shuttering Board Committee.

Our Service

1. Consultancy

Shop drawing, assembly drawing, and even send our supervisor to your site for training and supervision.

FAQ

1. Why Choose Us?

We are a more than 10 years professional manufacturer in formwork with high quality and competitive price.

2. What's your formwork guarantee?