Q1. What do you do?

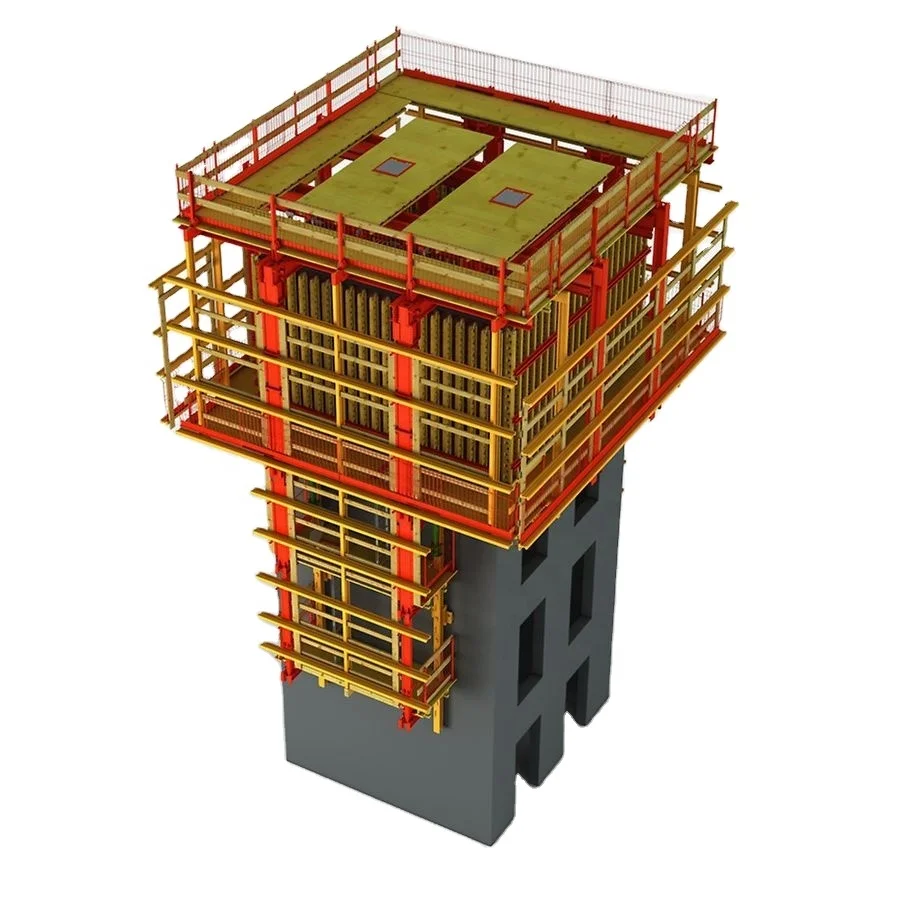

A: We manufacture and integrating existing formwork and scaffolding products to compose a optimium solution for pouring concrete structure in the field of housing, multi-story structure, high rise buildings, towers, sports stadiums, bridges, hydropower stations, industrial structures etc.

Q2. How many construction projects have you accomplished?

A: 400 both in China and abroad.

Q3. Have you accomplished any landmark?

A: Yes, we have. For example, PAFC (660 meters tall), The 21 Century Building, 2008 Beijing Olympic Main Stadium, CCTV New Site, Colombo Lotus Tower(Sri Lanka), Hong Kong-Zhuhai-Macau Bridge, Gezhouba Pubugou Hydropower Station etc.

Q4. What can you do for us?

A.We offer our suggestions, drawings of formwork layout, and quotations to the owners, design institutes, or contractors of the construction projects.

B.We sell our products to the contractors, building companies, or trading companies

C.We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D.We provide remote or on-site instruction to the builders.

Q5. What do you need in order to make a brief design and quotation when we have a construction project to be built?

A: Structural drawing and section drawing.

Q6. How long does it take to make a brief design and quotation after we offer the structural drawing?

A: In general, it takes 5~7 days based on specific requirements of construction project.

Q7. How long dose it take to manufacture the products after the signing of contract?

A: In general, it takes 30~60 days based on the type and quantity of products to be produced.

Q8. Are your products available for leasing?

A: Our products are available for leasing in Indonesia, Singapore, Dubai, Australia, New Zealand. It depends on local relevant regulations in other countries.