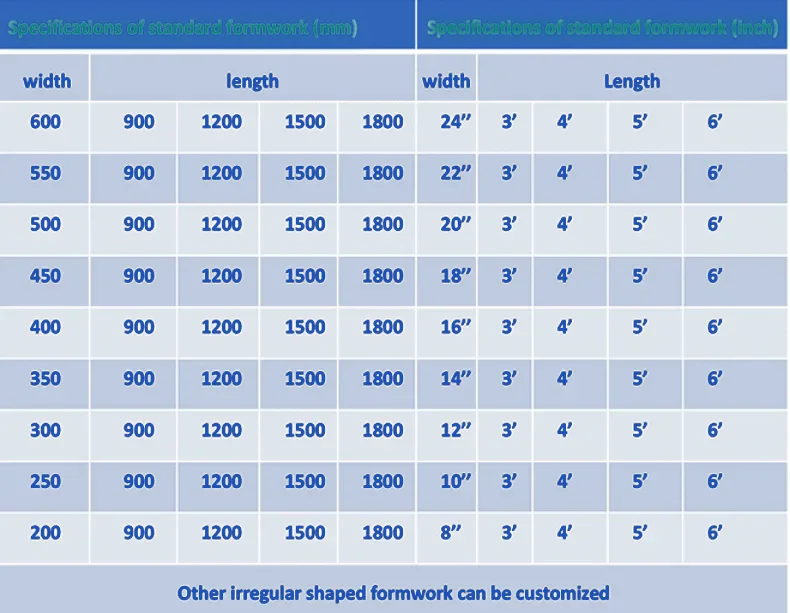

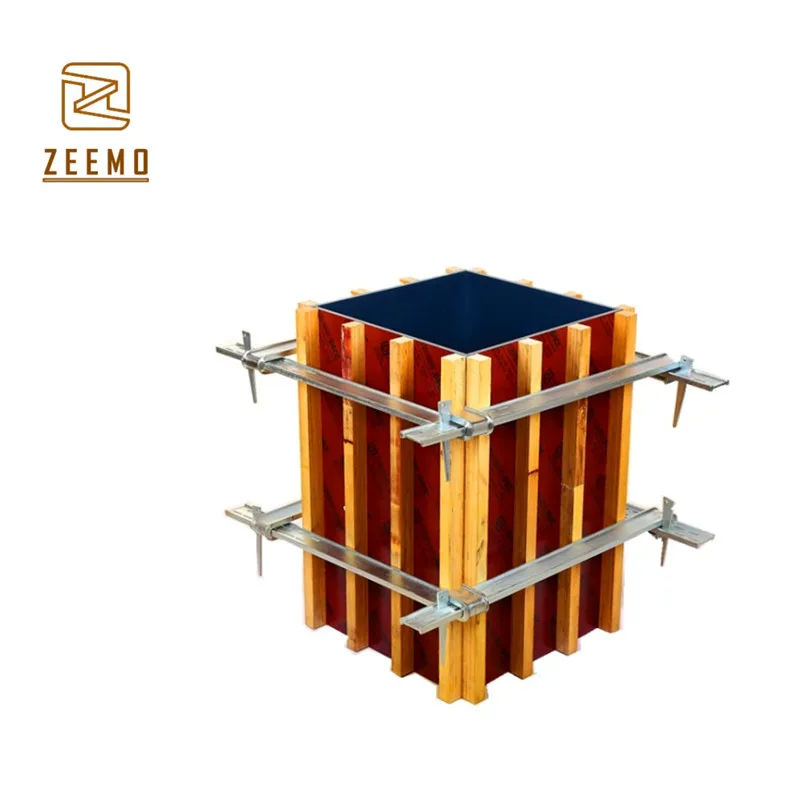

1. Light weight and large width

Since the panel is replaced with film faced plywood, the weight of this combined steel formwork can be reduced by 1/4~1/5;

Since the panel is replaced with film faced plywood, the weight of this combined steel formwork can be reduced by 1/4~1/5;

Due to the reduced weight of the steel frame film faced plywood formwork, the formwork width can be increased to facilitate operator handling and installation;

Due to the enlarged board width, the joints of formwork assembly are reduced.

2. Reduction in steel consumption

The steel frame film faced plywood formwork uses an average of about 20.4kg of steel per square meter, which is about 47.4% less than the combined steel formwork.

3. The formwork has small adsorption force and is easy to demould.

It has been determined that the adsorption force is only 1/6~1/7 of the steel formwork.

4. High turnover times

The number of times a formwork can be recycled is related to the operating conditions and management level. Under China's current management level, it can generally be recycled 50 times.

5. Good thermal insulation performance

The thermal conductivity of plywood is 0.17W/m.K, which is 1/360 of the steel plate surface, so it is beneficial to the insulation of concrete in winter.

6. Easy maintenance

When the plywood surface is damaged, the partially damaged surface can be repaired on site without replacing the panel. When one side is worn, the board can be turned over for use.

2. Reduction in steel consumption

The steel frame film faced plywood formwork uses an average of about 20.4kg of steel per square meter, which is about 47.4% less than the combined steel formwork.

3. The formwork has small adsorption force and is easy to demould.

It has been determined that the adsorption force is only 1/6~1/7 of the steel formwork.

4. High turnover times

The number of times a formwork can be recycled is related to the operating conditions and management level. Under China's current management level, it can generally be recycled 50 times.

5. Good thermal insulation performance

The thermal conductivity of plywood is 0.17W/m.K, which is 1/360 of the steel plate surface, so it is beneficial to the insulation of concrete in winter.

6. Easy maintenance

When the plywood surface is damaged, the partially damaged surface can be repaired on site without replacing the panel. When one side is worn, the board can be turned over for use.