Reusable film faced shuttering marine plywood for construction

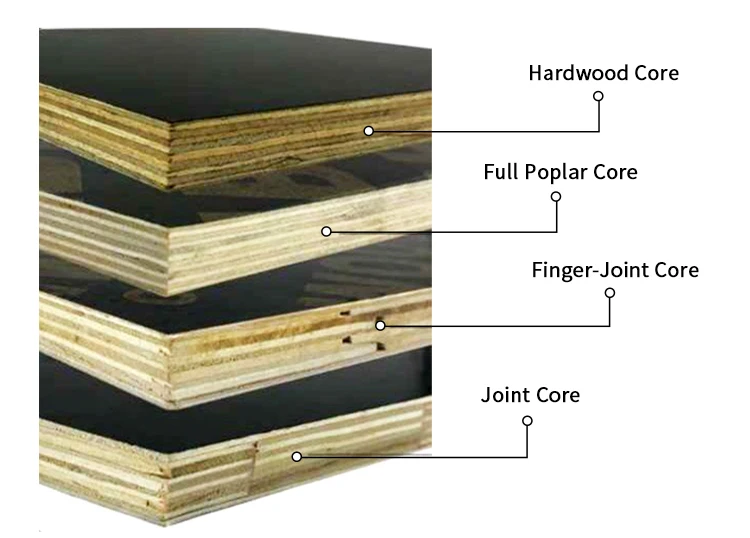

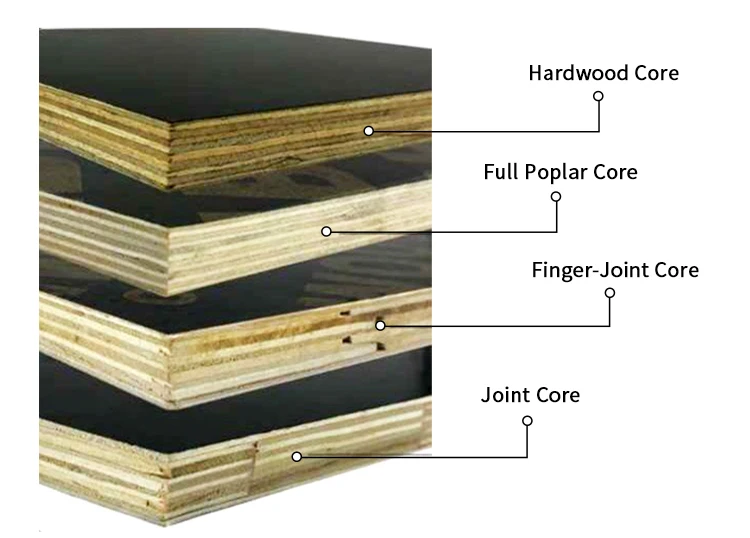

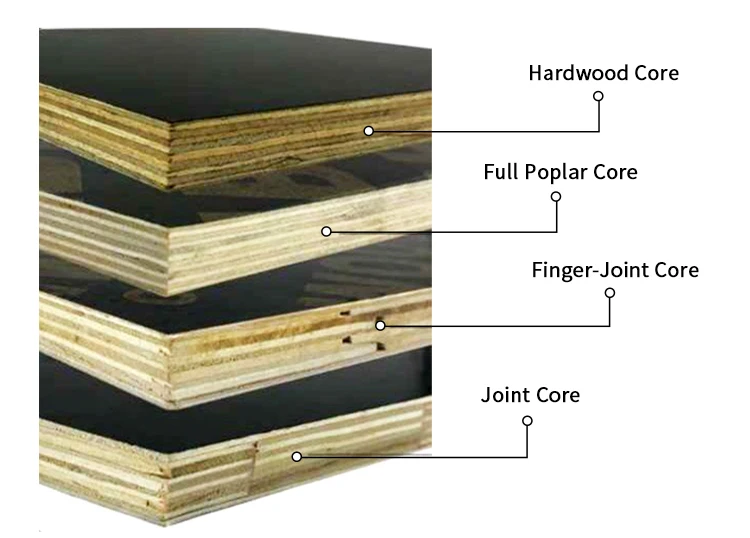

Zeemo film faced plywood materials mainly include eucalyptus, poplar, birch, miscellaneous wood, etc. They are economical and practical and are widely used in H20 formwork systems, steel frame formwork systems and other concrete buildings.

1). Sealing of Edges

Phenolic fabric film faced plywood edges are fully sealed at the factory and it is most important that all edges remain sealed. To obtain full value from a phenolic fabric film faced sheet any recut edges should be sealed as soon as possible with waterproof paint.

2). Sealing of Holes

Any holes made in fabric film faced formwork panels should also be sealed to prevent water entering. If water does enter it may cause swelling around the holes.

3). Cleaning and Repair

To obtain full life, cleaning should be carried out immediately after each use. Phenolic fabric film faced plywood may be wiped with release agent or cleaned with water and stiff brush. It may be necessary to use a hardwood scraper but care should be taken not to damage the plywood face. Do not use a wire brush or sharp metal scraper to dislodge hardened concrete.

4). Storage

Always clean and repair the formwork panels before storage. The formwork should then be stacked off the ground on level supports and under cover. Framed formwork panels should be stacked alternately face to face and back to back to avoid face damages by bolts etc. If panels are wet, do not allow them to dry too rapidly