| Availability: | |

|---|---|

| Quantity: | |

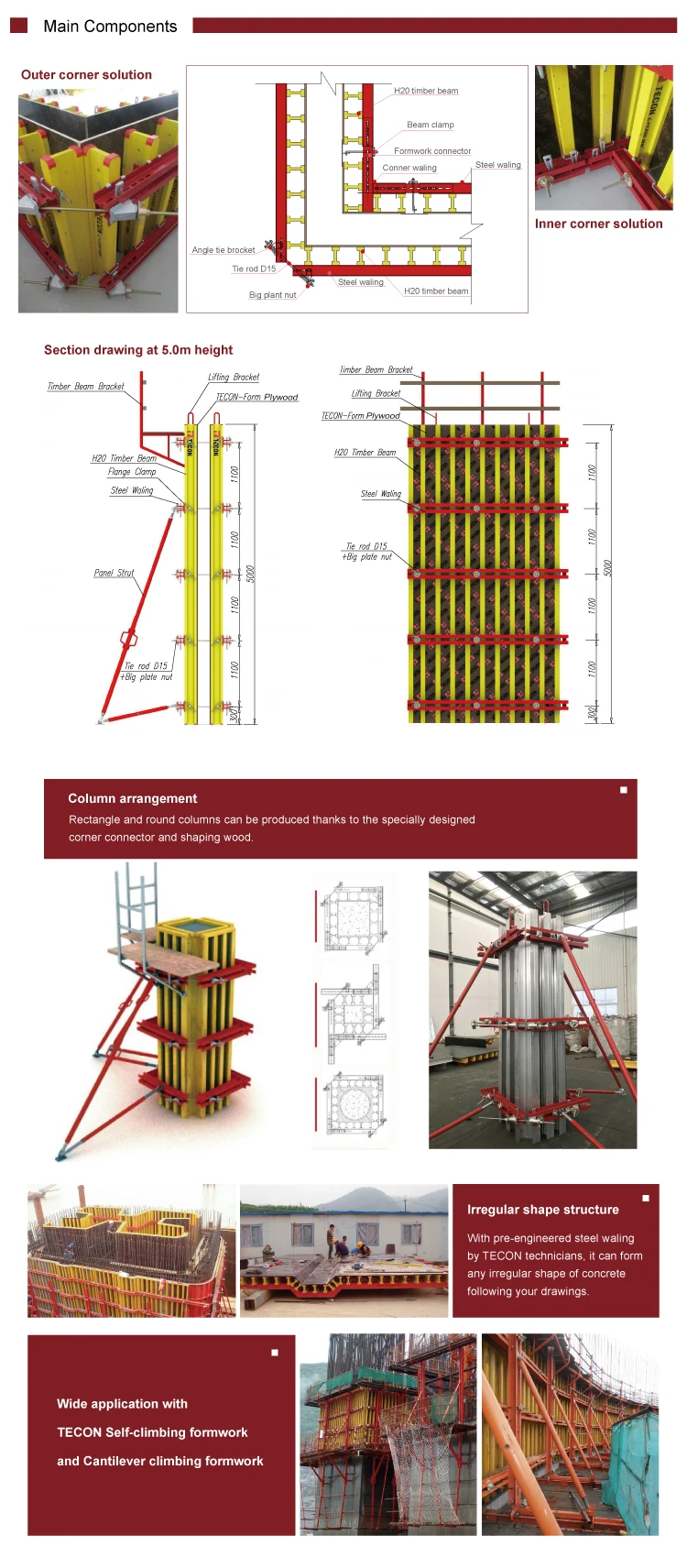

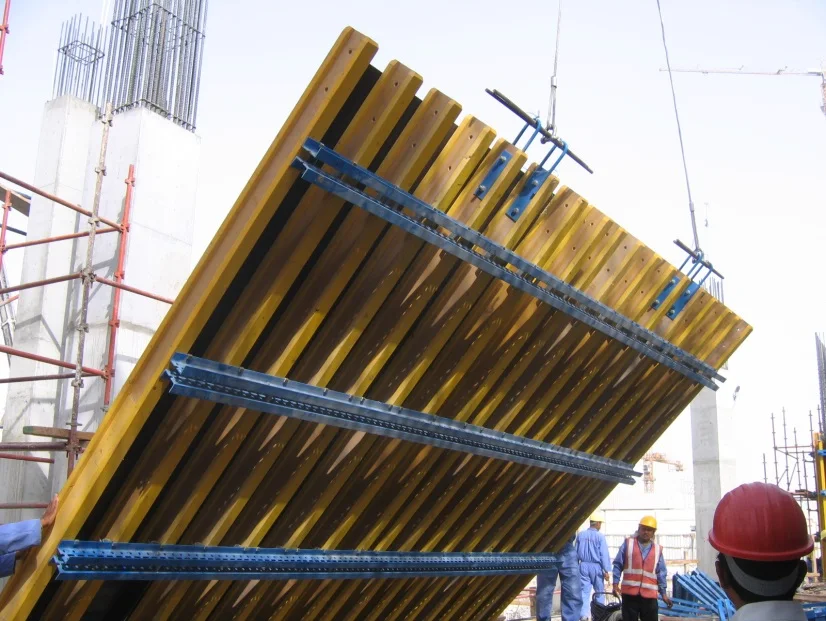

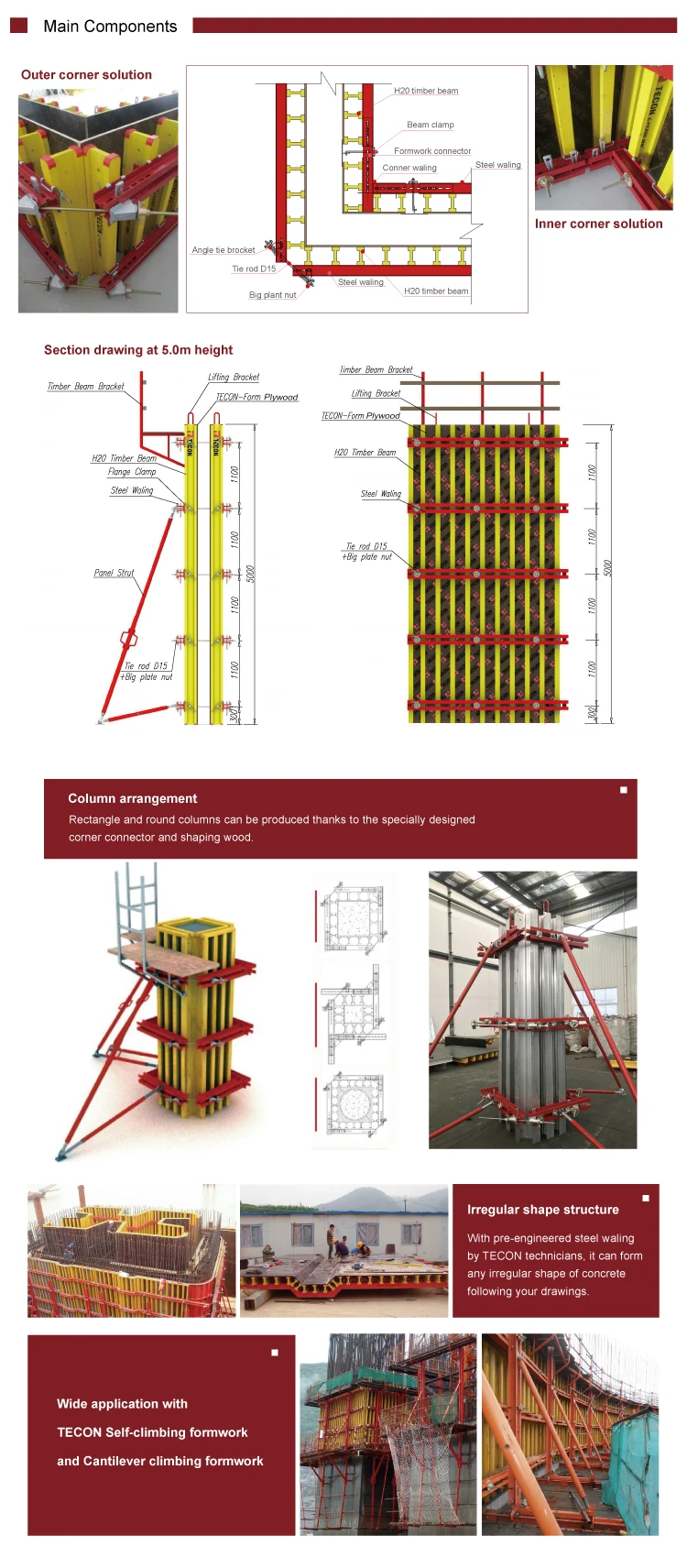

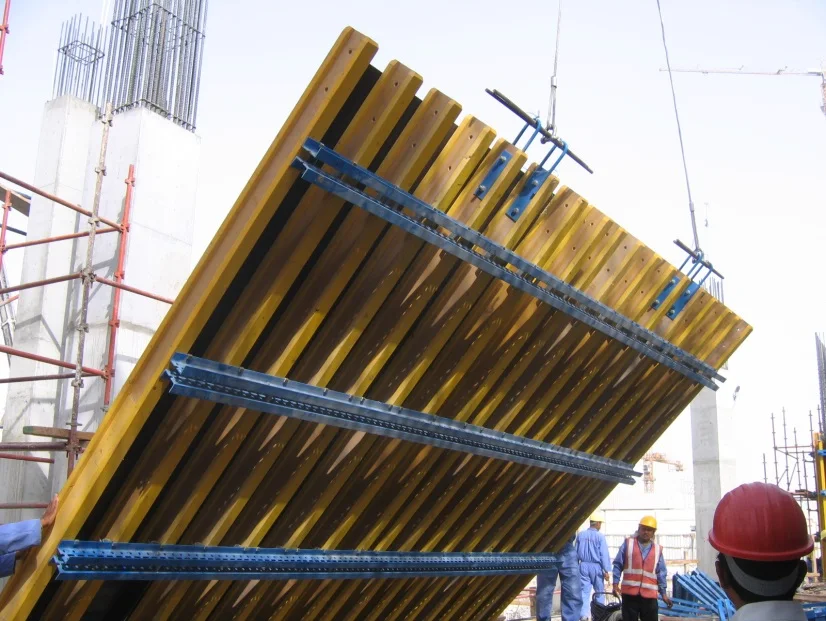

| ZEEMO wall concrete formwork H20 timber beam with plywood | |||

| MAX Pouring Height | Plywood | Weight | Leading Time |

| 9 meters | 18mm Hardwood Plywood | 65kg/SQM | 35 days |

A.We offer our suggestions, drawings of formwork layout, and quotations to the owners, design institutes, or contractors of the construction projects.

B.We sell our products to the contractors, building companies, or trading companies

C.We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D.We provide remote or on-site instruction to the builders.

| ZEEMO wall concrete formwork H20 timber beam with plywood | |||

| MAX Pouring Height | Plywood | Weight | Leading Time |

| 9 meters | 18mm Hardwood Plywood | 65kg/SQM | 35 days |

A.We offer our suggestions, drawings of formwork layout, and quotations to the owners, design institutes, or contractors of the construction projects.

B.We sell our products to the contractors, building companies, or trading companies

C.We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D.We provide remote or on-site instruction to the builders.