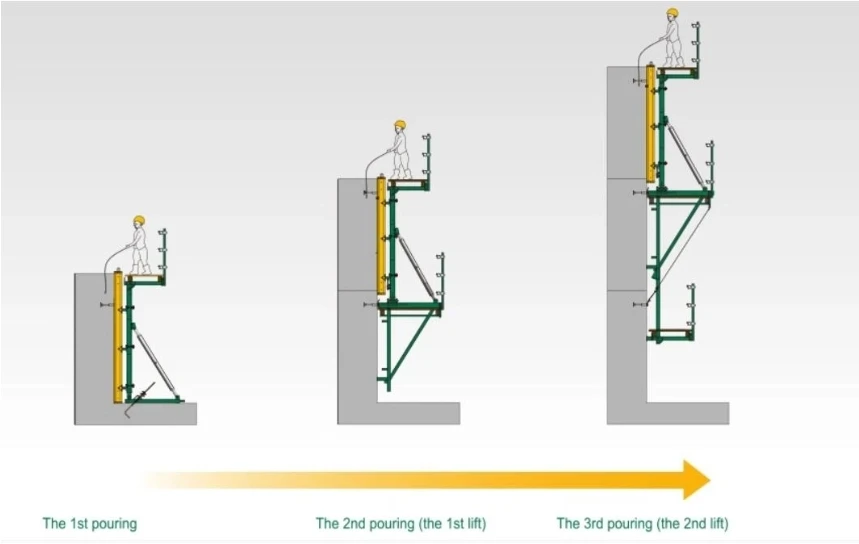

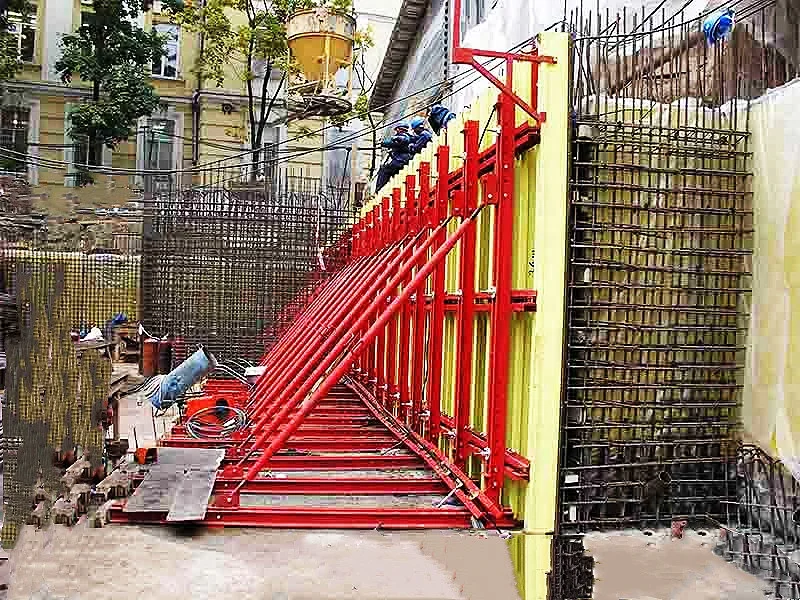

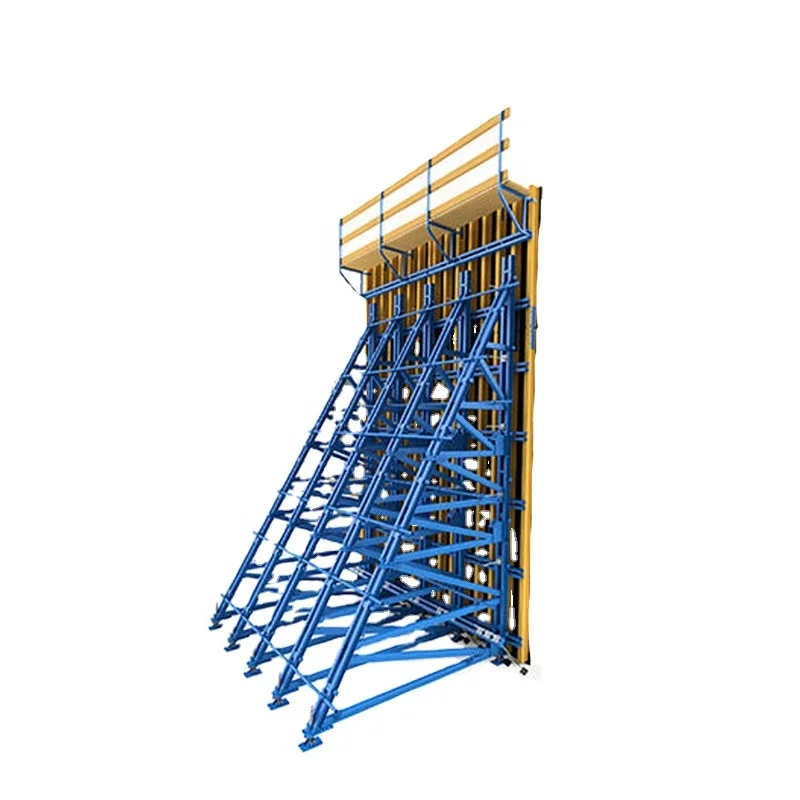

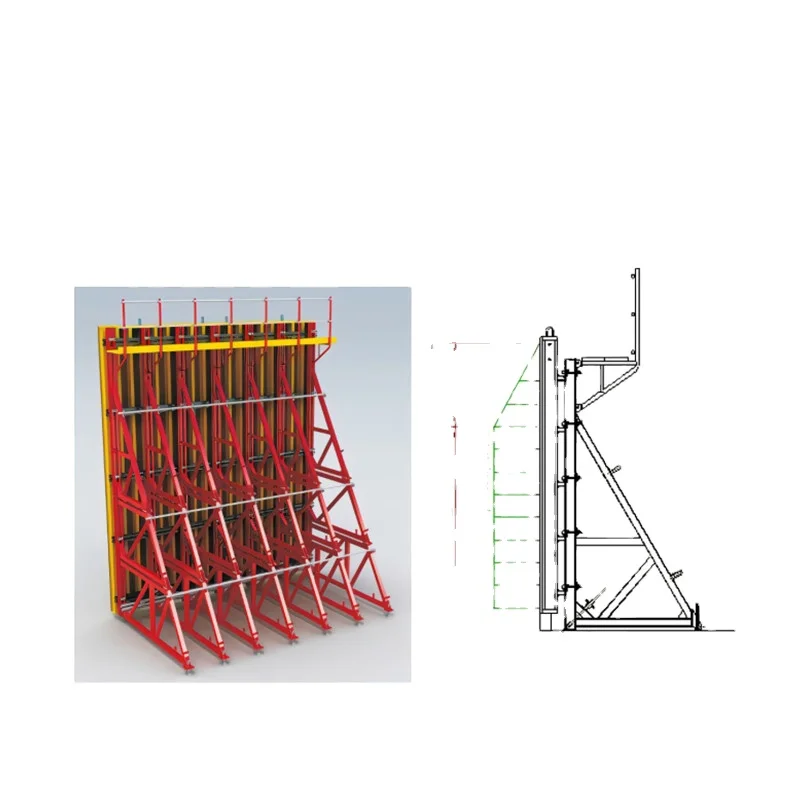

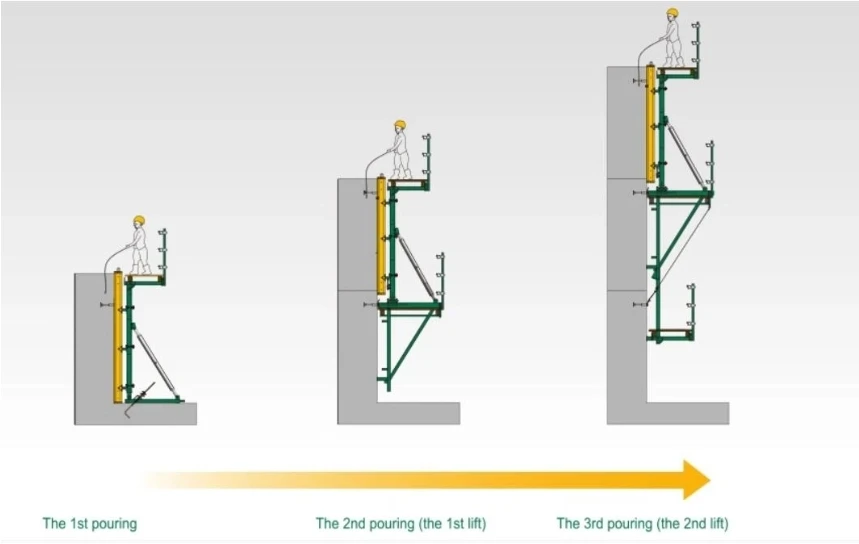

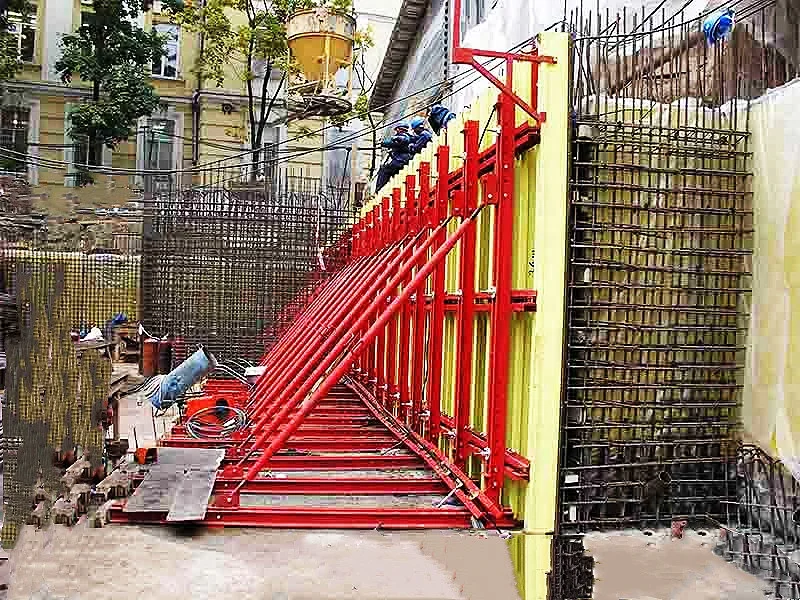

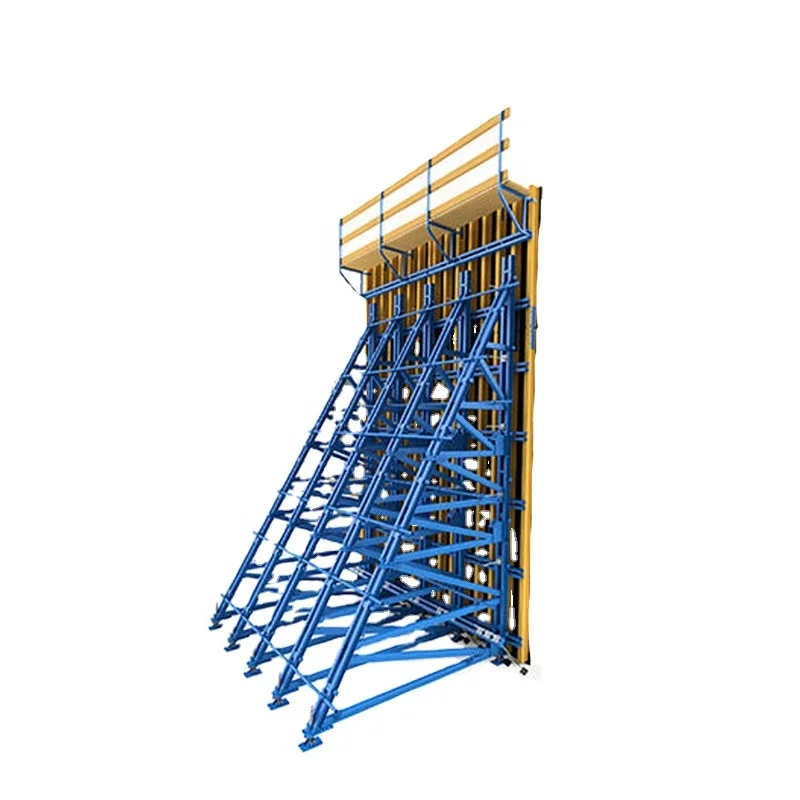

It is a system used in Metro Station (Subway), retaining wall, curtain wall, Dam, Pier, Guy Anchor, Tunnel, Underground, car park, Workshop and rebuilt areas, basement, sewage treatment factory with single sided mold space problem.

| Availability: | |

|---|---|

| Quantity: | |

ZM-SSW

Zeemo

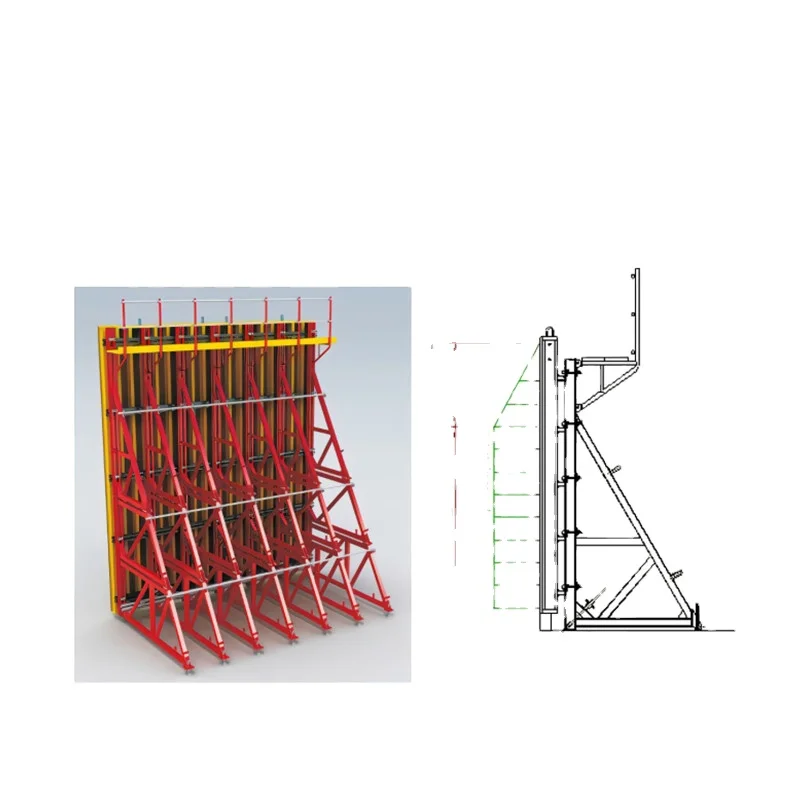

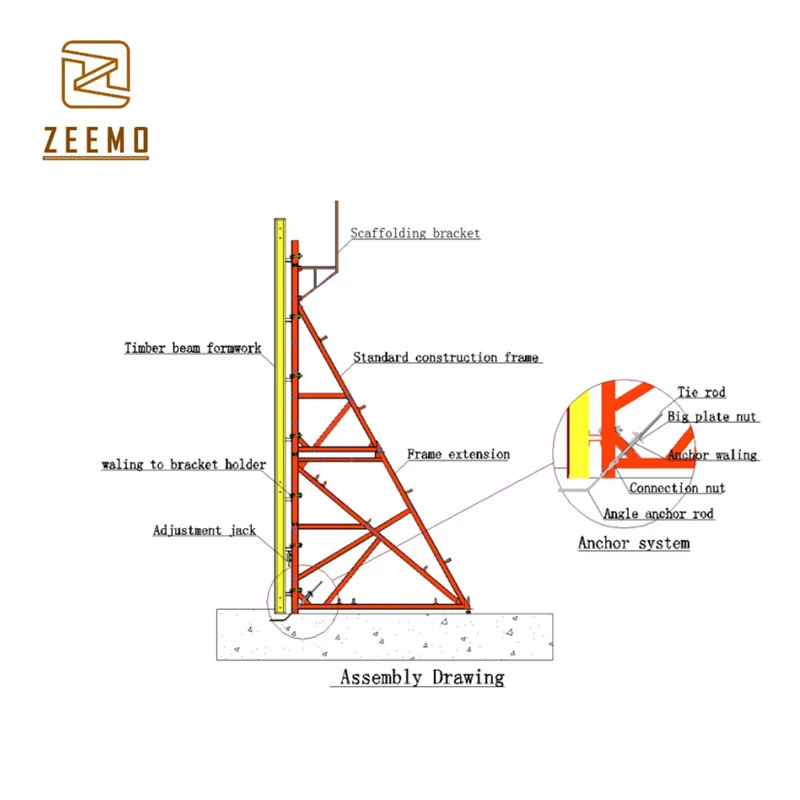

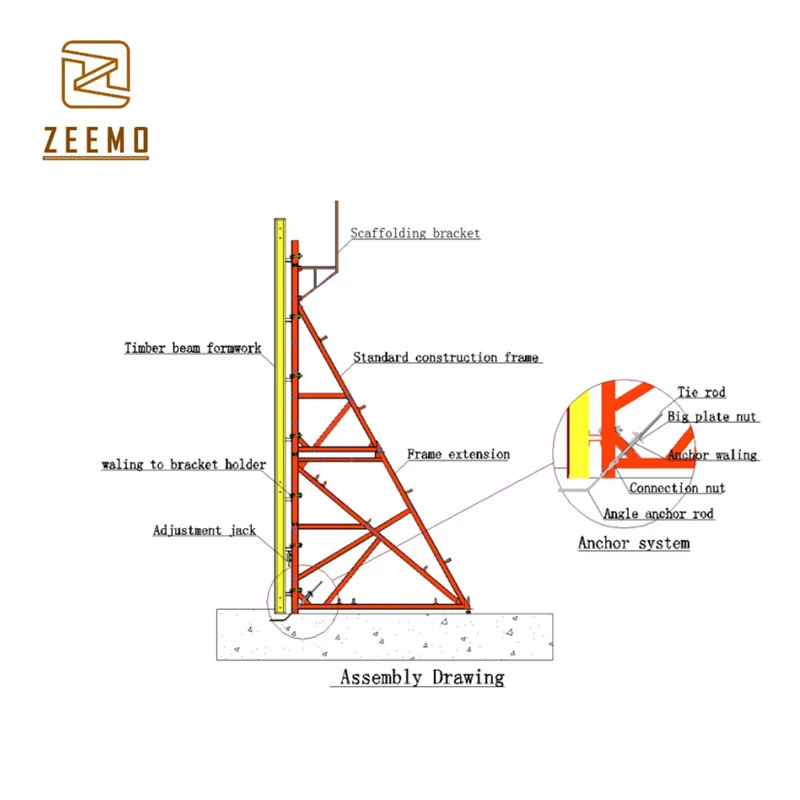

| WALING/WALER | 2*[12] Q235 |

| BEAM | H20 BEAM |

| PLYWOOD | 18MM FILM FACED PLYWOOD |

| ANCHOR SYSTEM | Tie rod, big plate nut, anchor waling, gasket, connection nut, angle anchor rod |

| ACCESSORIES | scaffolding bracket, waling bracket holder, adjustment jack |

| WALING/WALER | 2*[12] Q235 |

| BEAM | H20 BEAM |

| PLYWOOD | 18MM FILM FACED PLYWOOD |

| ANCHOR SYSTEM | Tie rod, big plate nut, anchor waling, gasket, connection nut, angle anchor rod |

| ACCESSORIES | scaffolding bracket, waling bracket holder, adjustment jack |