| Availability: | |

|---|---|

| Quantity: | |

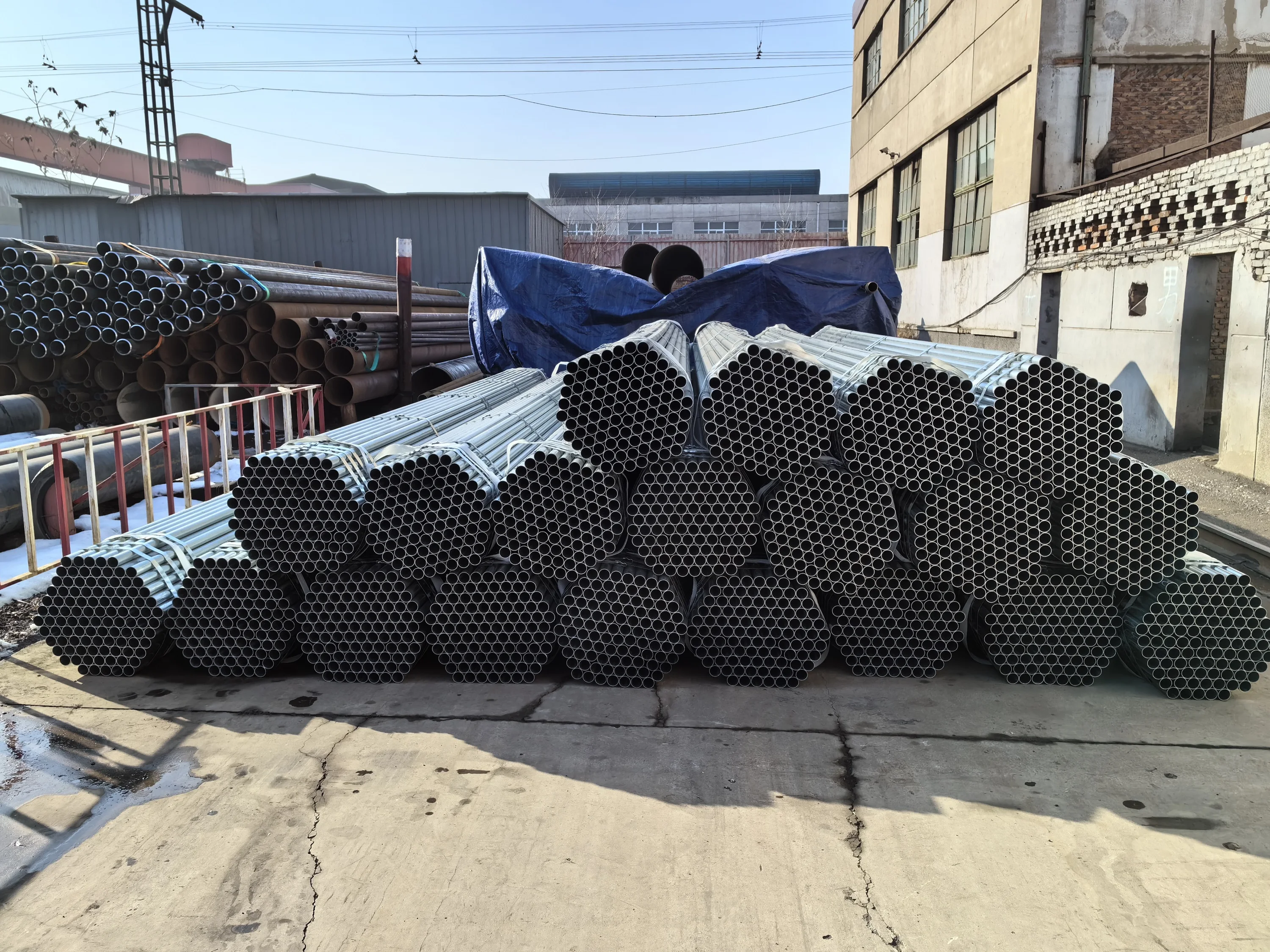

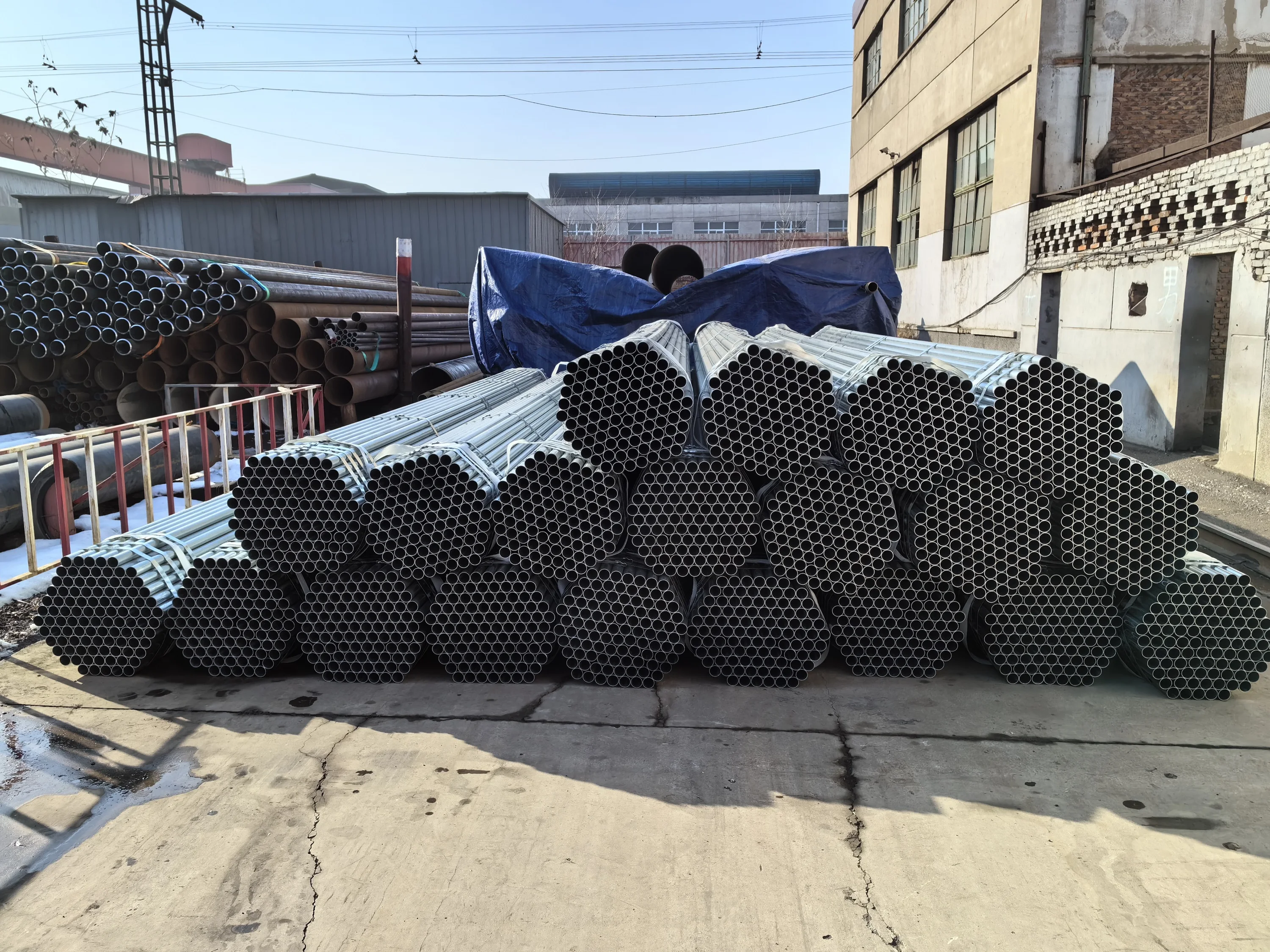

ZM-WF15

ZEEMO

| Square Tube | 20*20mm~ 500*500mm |

| Rectangular Tube | 20*30mm ~400*600 mm |

| Round Pipe | Ø19, Ø36, Ø48, Ø60, Ø72…Ø325 |

| Wall Thickness | 1.5mm-40mm |

| Standard | ASTM A53, BS1387-1985, API 5L standard |

| Material | Q195, Q235, Q345, ASTM A53 Gr.B, API 5L Gr.B |

| Finish | Hot dip galvanize / Pre galvanized |

| Procedure | Electronic Resistance Welded (ERW ) Double Submerged Arc Welded (DSAW) Electronic Fusion Welded (EFW) |

| Length | 2m,6m or custom |

| Delivery | Container, Bulk Vessel. |

| About Our Quality | 1) No damage, no bent |

| 2) no burrs or sharp edges and no scraps |

round steel - reinspection - peeling - fixed cutting - centering - heating - perforation - inspection - Pickling - Galvanizing - inspection - lubrication - cold dial-degreasing - volume treatment - Straightening - pipe cutting - pickling - finished product inspection - Marking - packaging – shipping

| Square Tube | 20*20mm~ 500*500mm |

| Rectangular Tube | 20*30mm ~400*600 mm |

| Round Pipe | Ø19, Ø36, Ø48, Ø60, Ø72…Ø325 |

| Wall Thickness | 1.5mm-40mm |

| Standard | ASTM A53, BS1387-1985, API 5L standard |

| Material | Q195, Q235, Q345, ASTM A53 Gr.B, API 5L Gr.B |

| Finish | Hot dip galvanize / Pre galvanized |

| Procedure | Electronic Resistance Welded (ERW ) Double Submerged Arc Welded (DSAW) Electronic Fusion Welded (EFW) |

| Length | 2m,6m or custom |

| Delivery | Container, Bulk Vessel. |

| About Our Quality | 1) No damage, no bent |

| 2) no burrs or sharp edges and no scraps |

round steel - reinspection - peeling - fixed cutting - centering - heating - perforation - inspection - Pickling - Galvanizing - inspection - lubrication - cold dial-degreasing - volume treatment - Straightening - pipe cutting - pickling - finished product inspection - Marking - packaging – shipping