| Availability: | |

|---|---|

| Quantity: | |

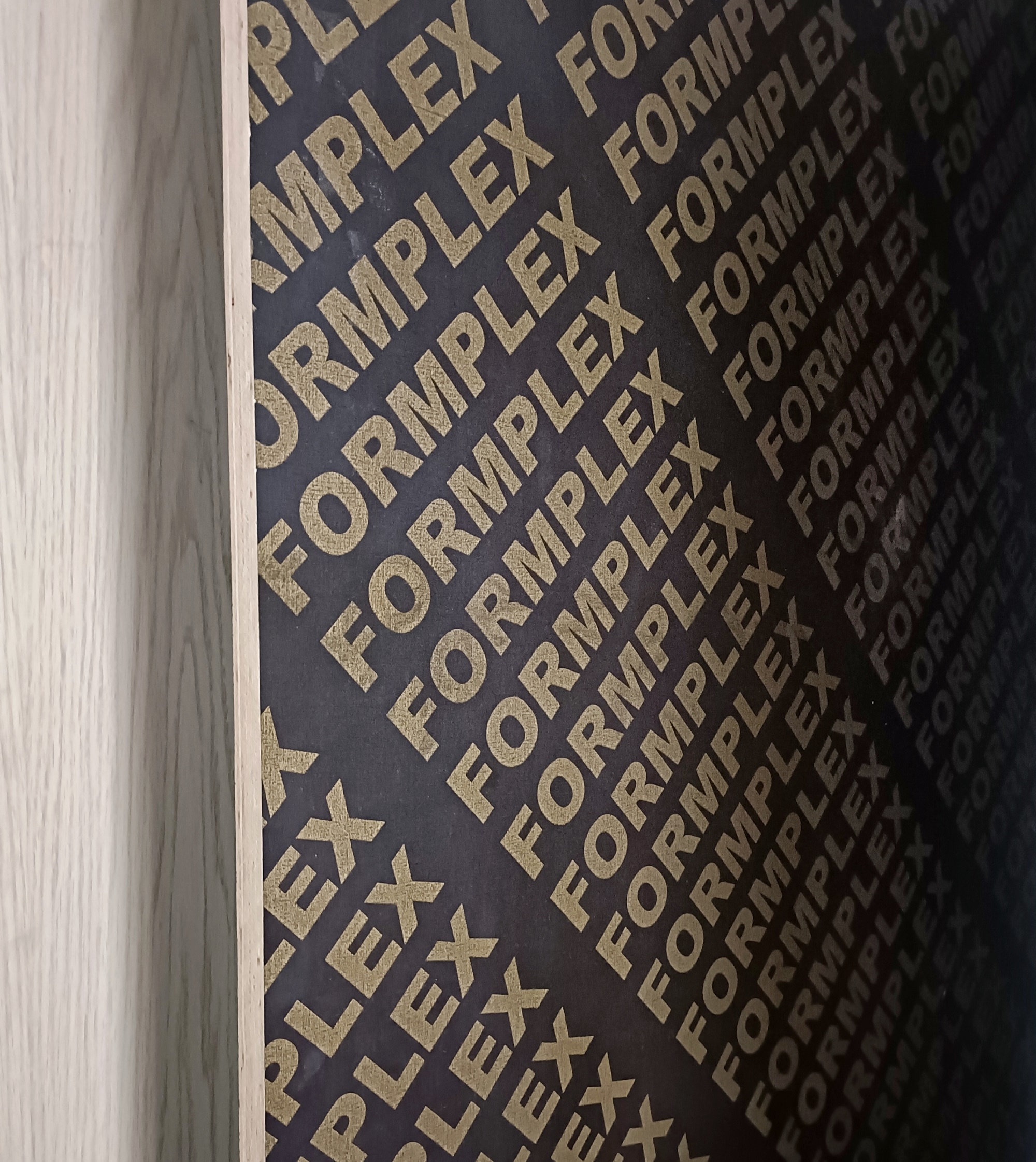

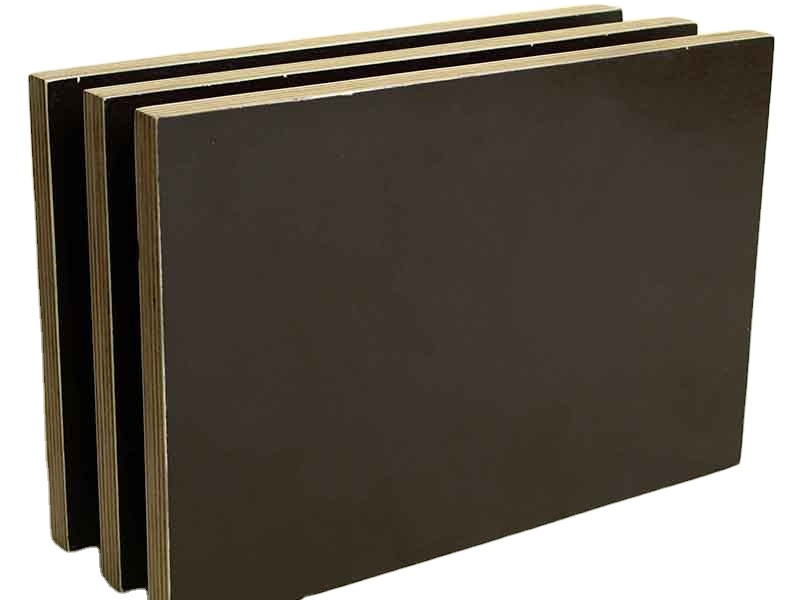

ZM-CW21

Zeemo

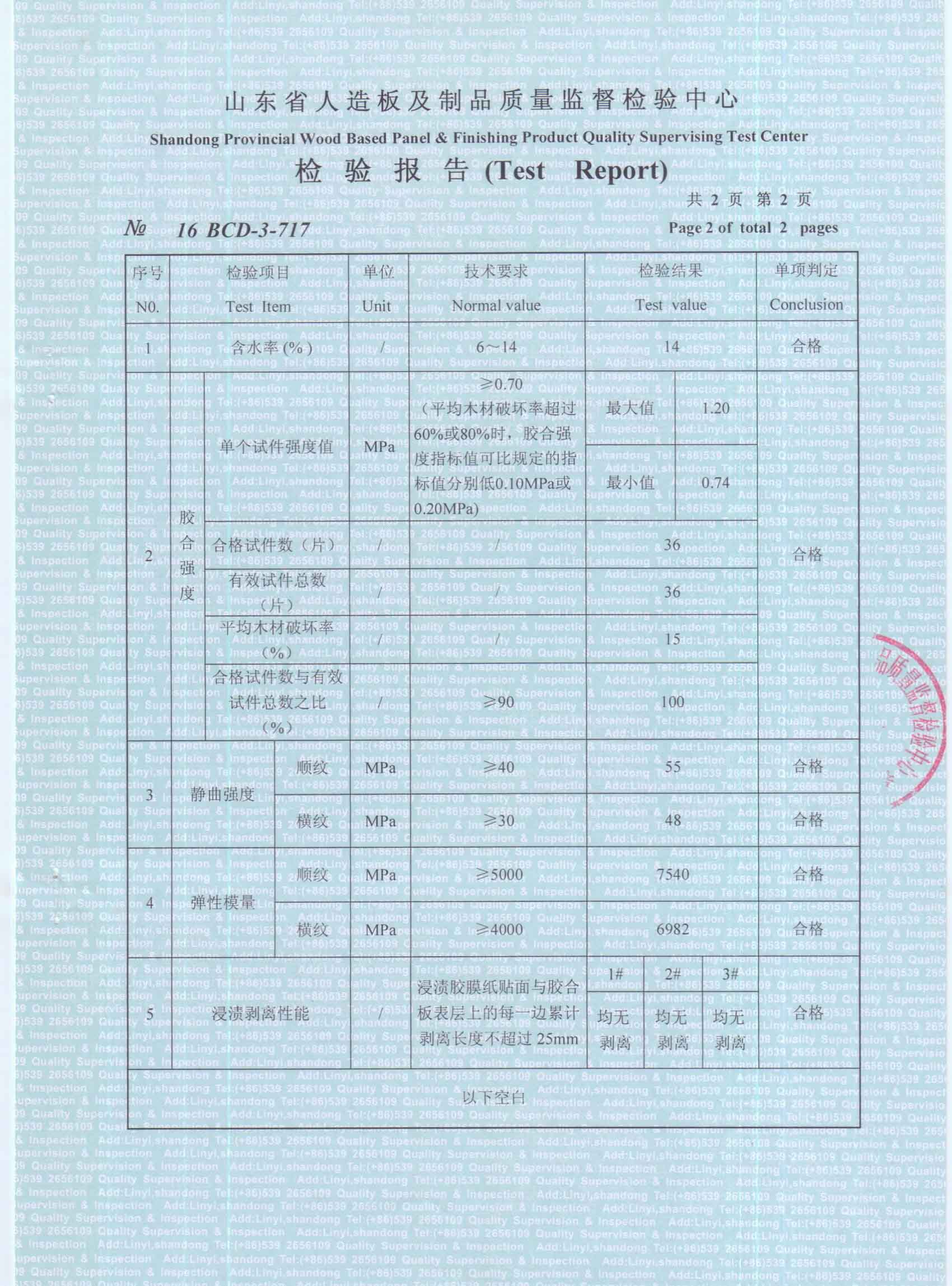

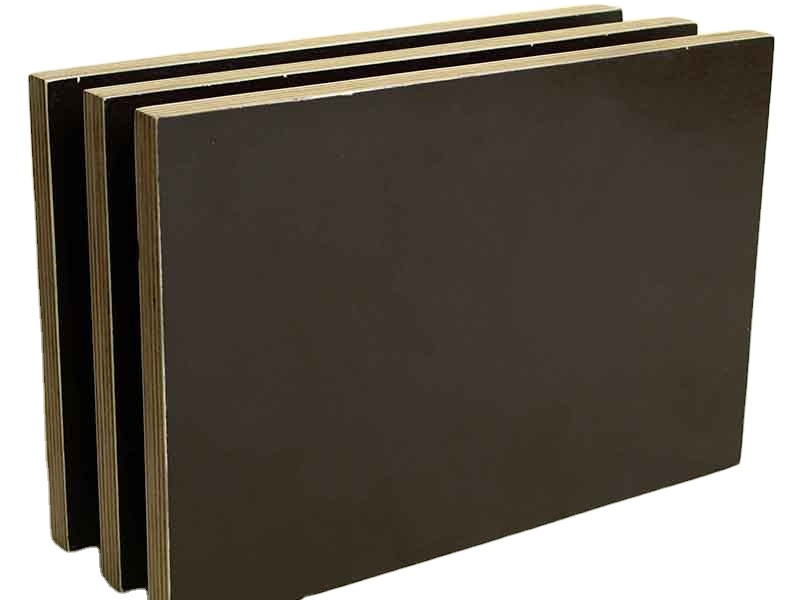

| Size (mm) | 915*1830, 1220*2440, 1250*2500 or upon request |

| Thickness (mm) | 9, 12, 15, 18, 21 +/-0.5mm |

| Core | Poplar, Birch, Eucalyptus,Combi or customized |

| Glue | Phenolic WBP, Melamine, MR |

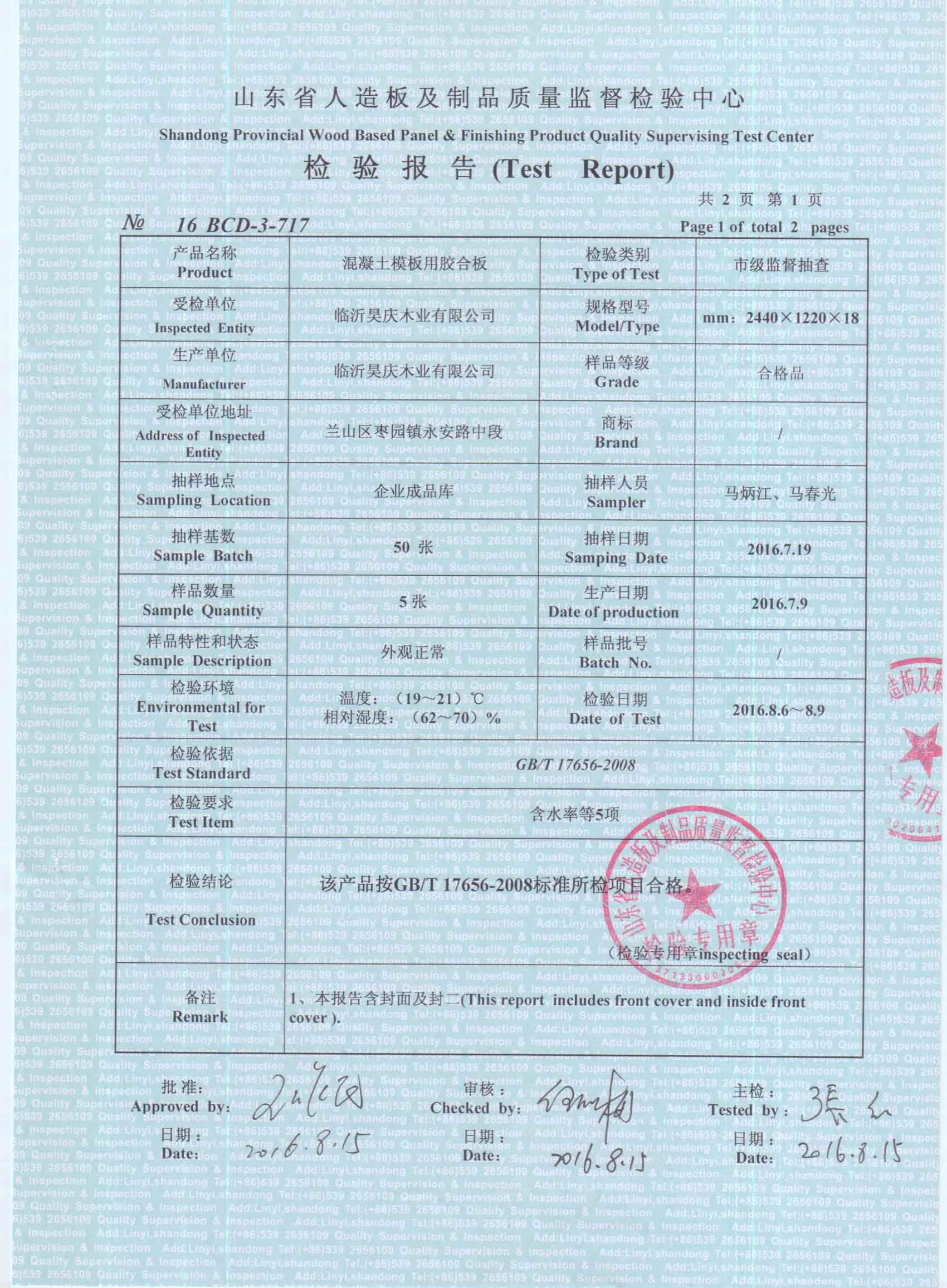

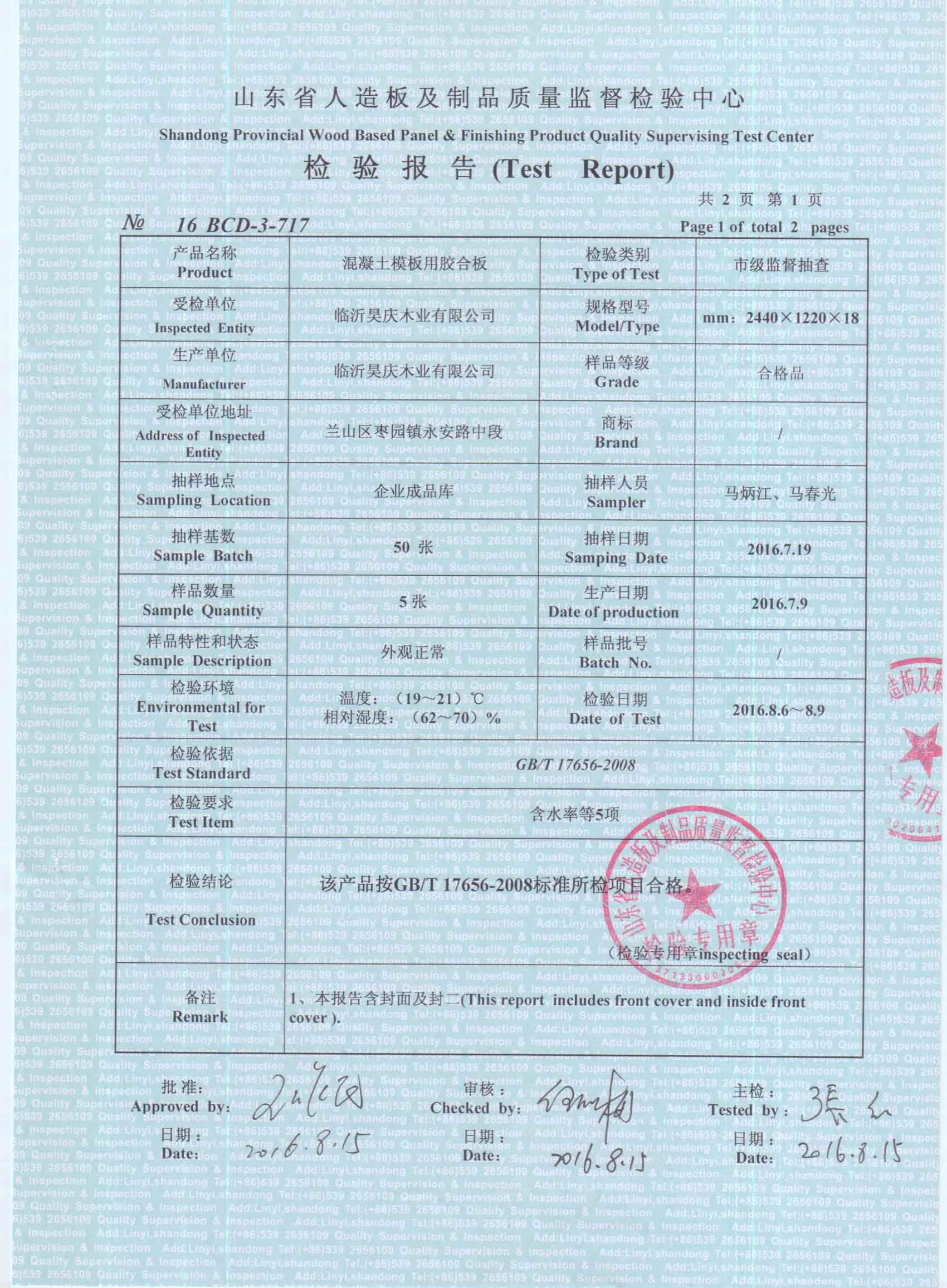

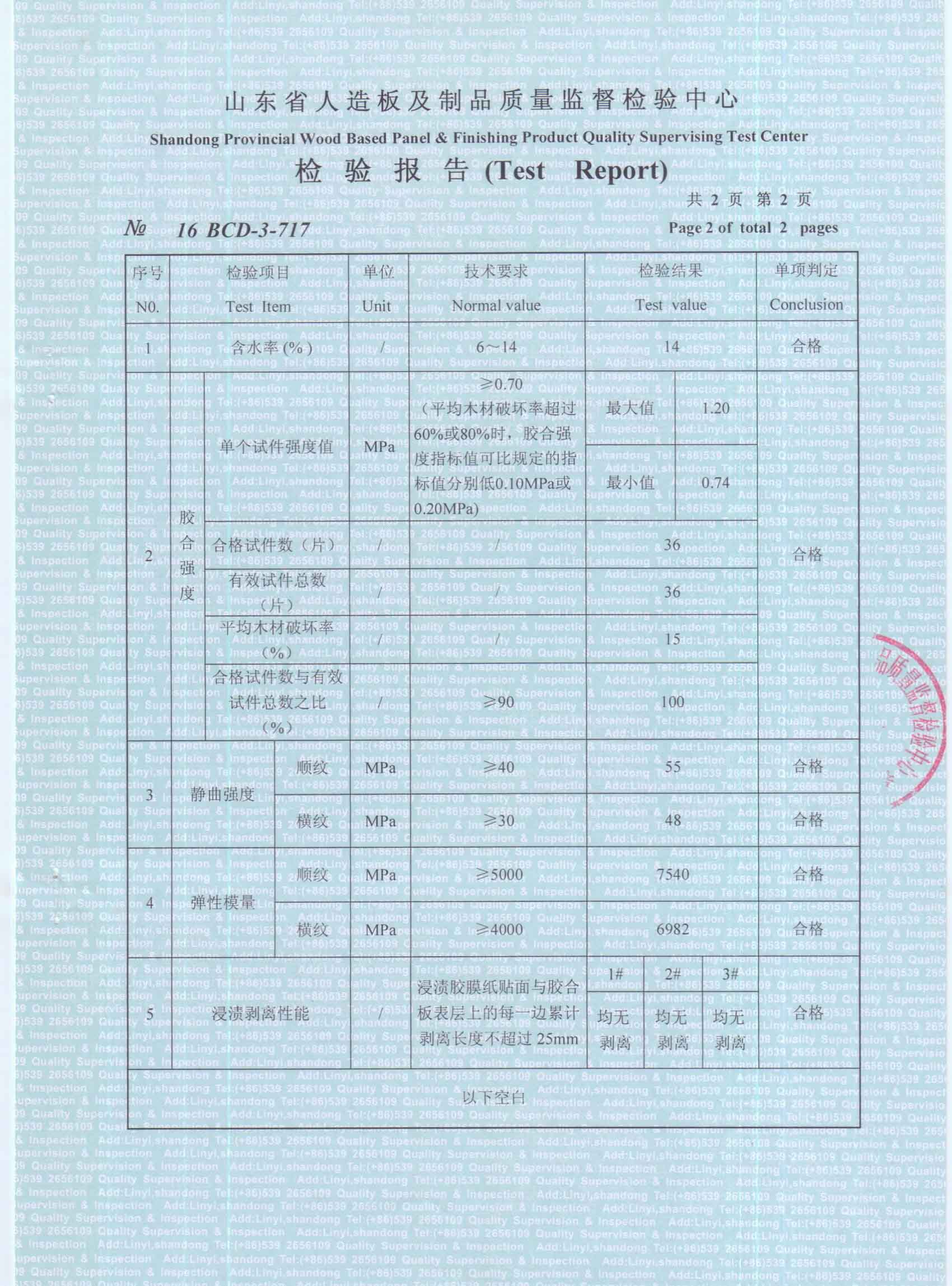

| Moisture Content | under 14%ex |

| Grade | Two time hot press / One time hot press / Finger-Joint |

Advantage

1. No edge warping, no breakage, no deformation, can be kept in boiling water for 24 hours. 2. Good performance and long turnaround time. 3. It is easy to remove the film, and the time is only 1/7 of the steel mold. 4. Make the concrete surface more smooth and beautiful, which is convenient for decoration and saves the process of plastering. 5. This can ease contact 30% of the time for a project. 6. Corrosion resistance, will not pollute the concrete surface. 7. Good thermal insulation performance, which is beneficial to winter construction. 8. The product can be made into warped plywood. 9. Nails, saws, and drills are superior to bamboo and steel molds, and can be processed into different types.

2. Good performance and long turnaround time. 3. It is easy to remove the film, and the time is only 1/7 of the steel mold. 4. Make the concrete surface more smooth and beautiful, which is convenient for decoration and saves the process of plastering. 5. This can ease contact 30% of the time for a project. 6. Corrosion resistance, will not pollute the concrete surface. 7. Good thermal insulation performance, which is beneficial to winter construction. 8. The product can be made into warped plywood. 9. Nails, saws, and drills are superior to bamboo and steel molds, and can be processed into different types.

| Size (mm) | 915*1830, 1220*2440, 1250*2500 or upon request |

| Thickness (mm) | 9, 12, 15, 18, 21 +/-0.5mm |

| Core | Poplar, Birch, Eucalyptus,Combi or customized |

| Glue | Phenolic WBP, Melamine, MR |

| Moisture Content | under 14%ex |

| Grade | Two time hot press / One time hot press / Finger-Joint |

Advantage

1. No edge warping, no breakage, no deformation, can be kept in boiling water for 24 hours. 2. Good performance and long turnaround time. 3. It is easy to remove the film, and the time is only 1/7 of the steel mold. 4. Make the concrete surface more smooth and beautiful, which is convenient for decoration and saves the process of plastering. 5. This can ease contact 30% of the time for a project. 6. Corrosion resistance, will not pollute the concrete surface. 7. Good thermal insulation performance, which is beneficial to winter construction. 8. The product can be made into warped plywood. 9. Nails, saws, and drills are superior to bamboo and steel molds, and can be processed into different types.

2. Good performance and long turnaround time. 3. It is easy to remove the film, and the time is only 1/7 of the steel mold. 4. Make the concrete surface more smooth and beautiful, which is convenient for decoration and saves the process of plastering. 5. This can ease contact 30% of the time for a project. 6. Corrosion resistance, will not pollute the concrete surface. 7. Good thermal insulation performance, which is beneficial to winter construction. 8. The product can be made into warped plywood. 9. Nails, saws, and drills are superior to bamboo and steel molds, and can be processed into different types.