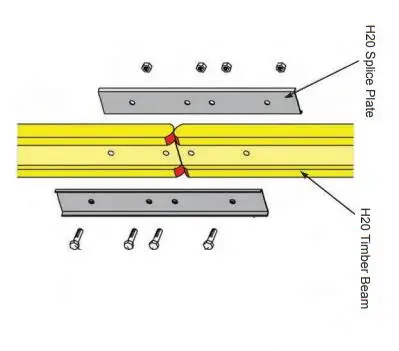

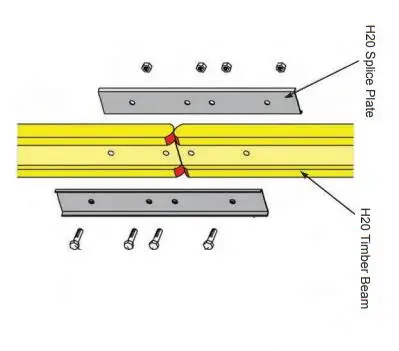

As required, standard holes can be drilled in the two ends of timber beams. We can lengthen the timber beam by end-to-end join. According to customers’ demand, we can produce timer beams with any length.

| Availability: | |

|---|---|

| Quantity: | |

H20

ZEEMO

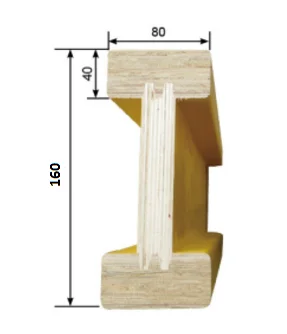

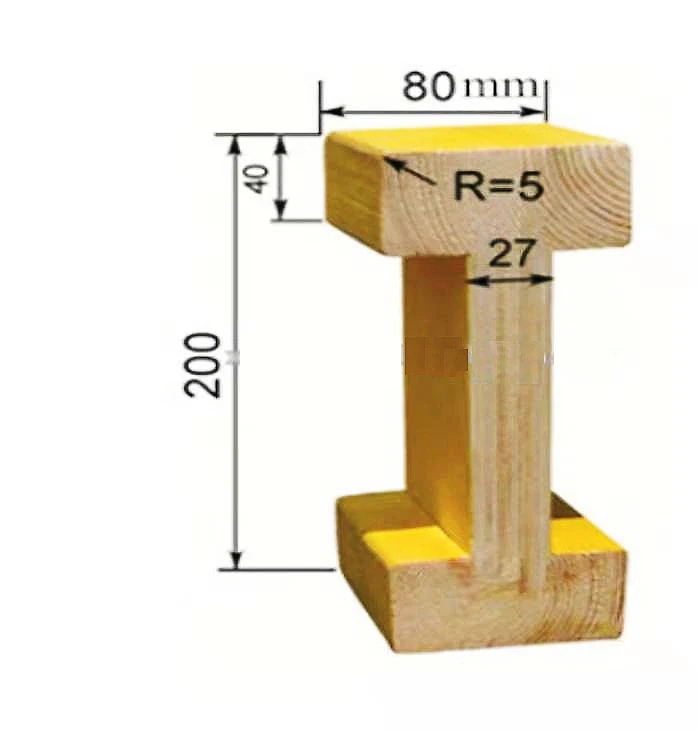

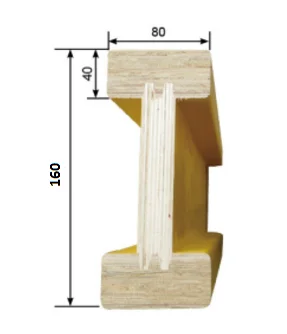

| Size | Height 200/160/140/120mm |

| Available length (M) | Any length within 5.9m can be customized |

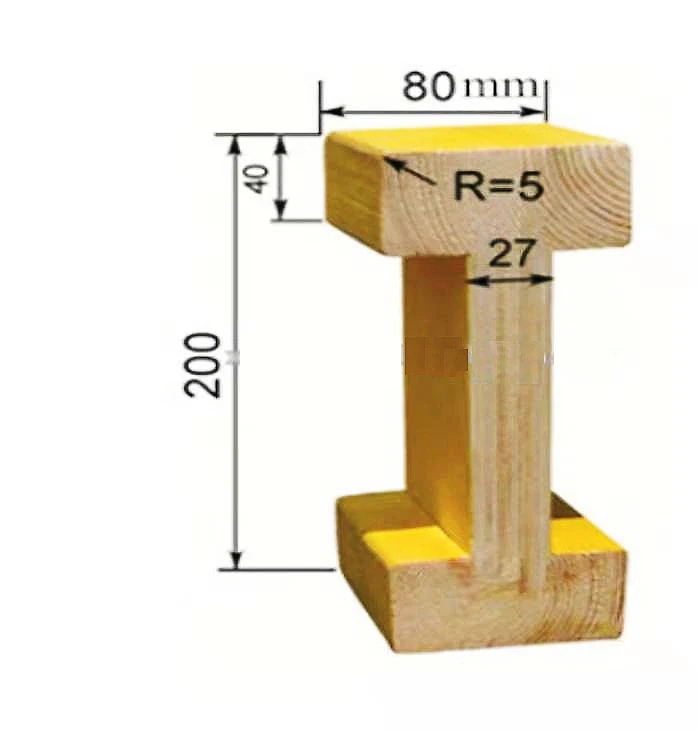

| Flange | Finnish spruce 80*40mm |

| Web | Plywood 27 * 150mm |

| Glue | WBP glue |

| Weight | 4.5 kg/m |

| Moisture Content | 12% ex workshop |

| Test Items | European Standard | Test Data | ||

| Allowable Values DIN 1052-1:1988-04 | Limits of load-bearing Capacity DIN 1052:2008-12/Eurocode 5 | H20 Beam | H20 Beam ECO | |

| Shearing Resistance (KN) | 11 | 23.9 | 29.13 | 37.22 |

| Bending Resistance( KN ) | 5 | 10.9 | 15.74 | 19.77 |

| Bearing Resistance (KN) | 22 | 47.8 | 50.20 | 63.30 |

| Size | Height 200/160/140/120mm |

| Available length (M) | Any length within 5.9m can be customized |

| Flange | Finnish spruce 80*40mm |

| Web | Plywood 27 * 150mm |

| Glue | WBP glue |

| Weight | 4.5 kg/m |

| Moisture Content | 12% ex workshop |

| Test Items | European Standard | Test Data | ||

| Allowable Values DIN 1052-1:1988-04 | Limits of load-bearing Capacity DIN 1052:2008-12/Eurocode 5 | H20 Beam | H20 Beam ECO | |

| Shearing Resistance (KN) | 11 | 23.9 | 29.13 | 37.22 |

| Bending Resistance( KN ) | 5 | 10.9 | 15.74 | 19.77 |

| Bearing Resistance (KN) | 22 | 47.8 | 50.20 | 63.30 |