| Availability: | |

|---|---|

| Quantity: | |

ZM-PS15

Zeemo

| Production Specifications | |

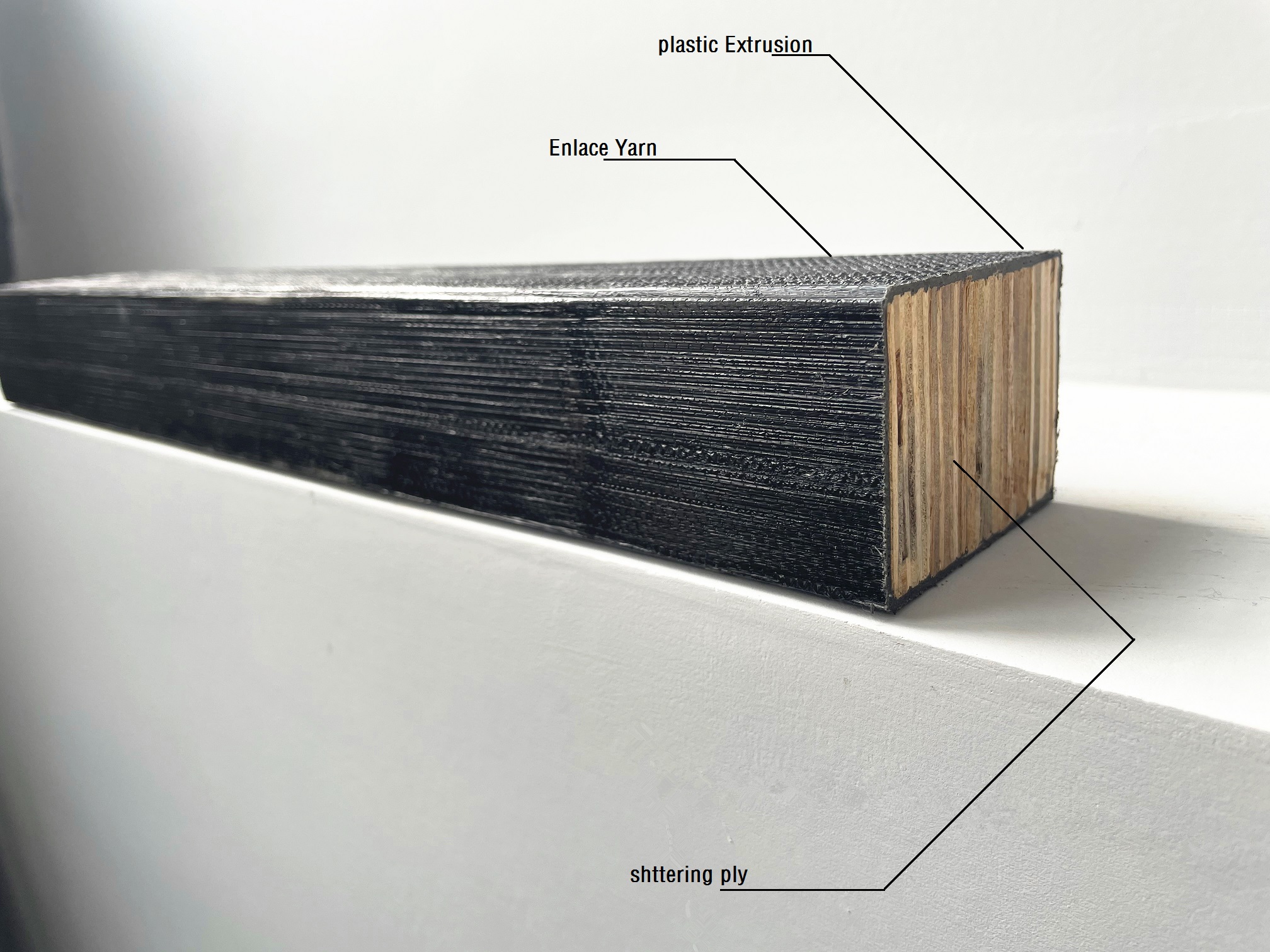

| Name | 2022 New Design Reuse 200 times Lumber Beam - Coated with Black Plastic Rigid Stud For Formwork |

| Size | 50mm x 70mm / 40 mm x 60mm |

| Thickness | 3 Meters or as request |

| Thickness Tolerance | +/-0.5mm |

| Surface Treatment | Coated with Anti-Slip Black Plastic |

| Core | Recycle Plywood |

| Glue | Phenolic ,WBP ,MR |

| Certification | ISO ,CE,CARB ,FSC |

| Moisture Content | 8%~14% |

| MOQ | 100 Meters |

| Payment Terms | T/T or L/C |

| Delivery Time | Within 2-3 weeks upon down payment or upon opening of L/C |

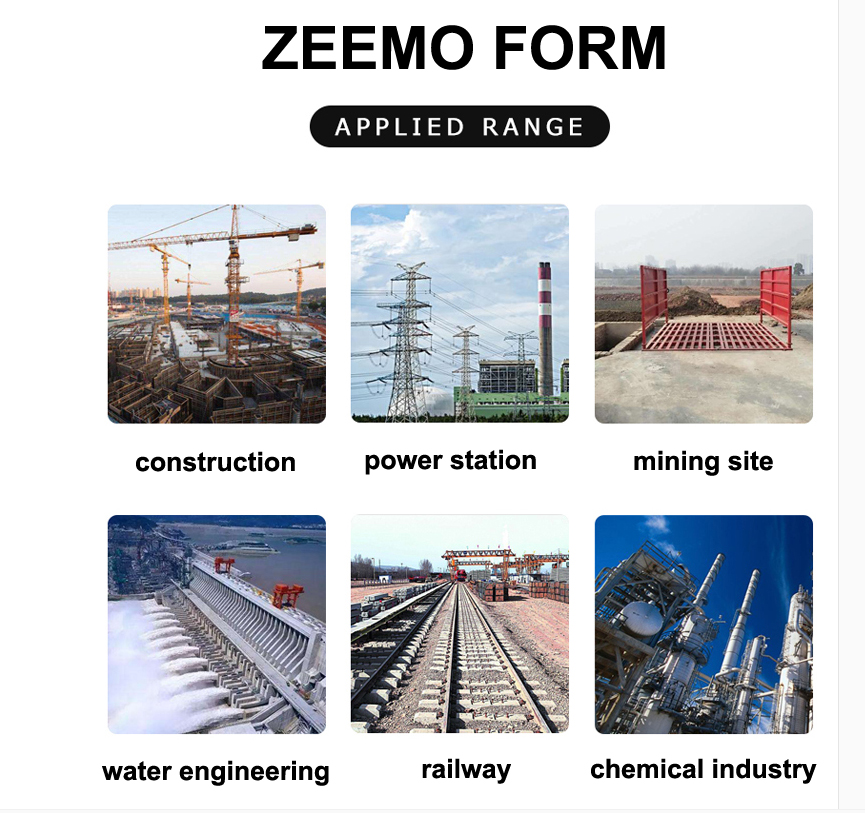

| Features | We called it "Rigid stud " in China this is designed & Produced in this year and instantly hot sale in Chinese market as its competitive price & Durable and Rigid feature . As it's made of Recycle plywood and covered with Anti-Slip Plastic resin outside , So it is of Super waterproof and Highly Bearing Strength feature. This lumber beams can be used many times , Using this lumber beam can reduce the material waste .It's good for our environment . |